So this weekend i really wanted to complete my feed-line for the 6BTV, its been ‘dug up’ for a few weeks and its case of making up the coax to feed into it. I’ve made many feedlines/patch cables with other coax and SO239 and PL259, but the M&P coax and connectors, well, are just really testing my patience.

The video for making this cable up, makes it look so simple, even this young lady (ND2L) can do it.

And the M&P official video makes it look easy enough

I’m using ExtraFlex bury, so it requires that 5mm incision to get the collar in.

3m tae

without

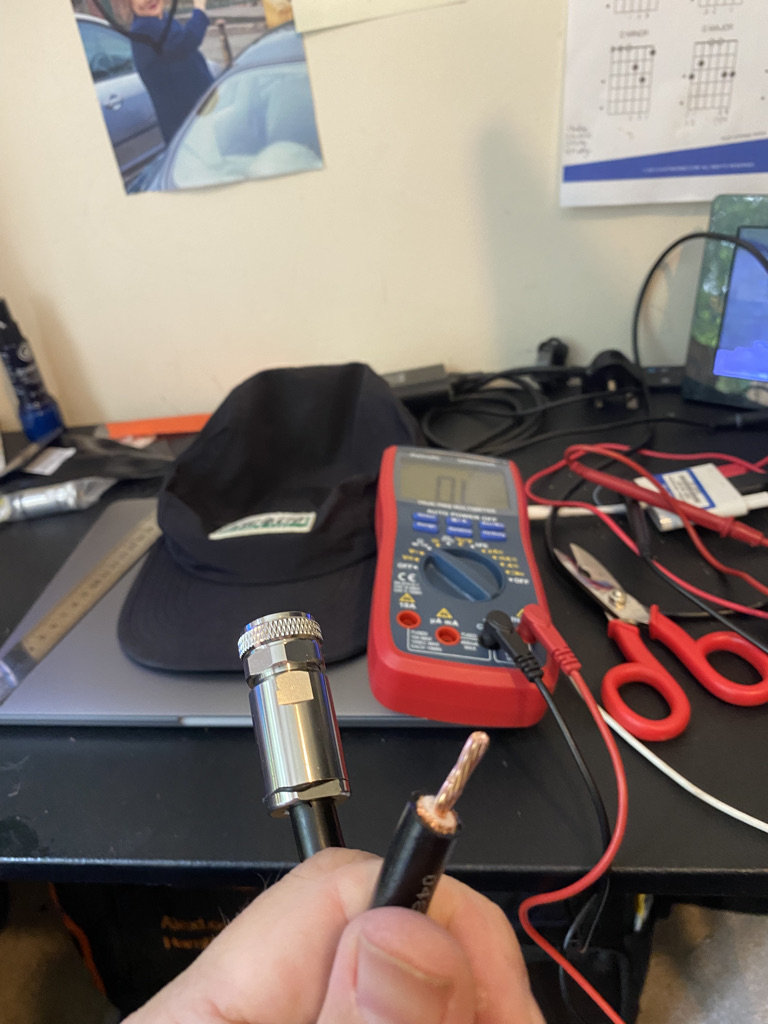

testing connectivity

I tried soldering, cutting and fitting the plugs as per the videos. On my first attempt i didnt get a good result on the resistance, but thought to give a try anyway, but yep, it didnt work.

I stripped everything down and tried again, I only have a metal ruler for measuring lengths, but done i best i could with it, and i dont have a decent knife, i actually ended up cutting my finger and blood was everywhere 🙁

I tried again and was frustated that again i didnt get the resistance outputs that was needed for an installlation. I cut the ends of the cable off. Repeat *4. On the 4th time it was now 20:00 BST and I was getting very tired of doing this, so just stripped everything back and had a rest.

Fast forward 12 hours I took a look at what the problems could be in my method. One the measurement was not good, the ruler wasnt good enough for the job, and more critically the injury from the blade was bad. I’ve ordered a measurement tool and a proper stanley knife. I’m really hopeful I can get this to work, the cable and plugs have cost *alot* and more importantly have cost me alot in time now.

TL/DR – use the right and safe tools when working with coax and plugs (I’m) not familiar with.