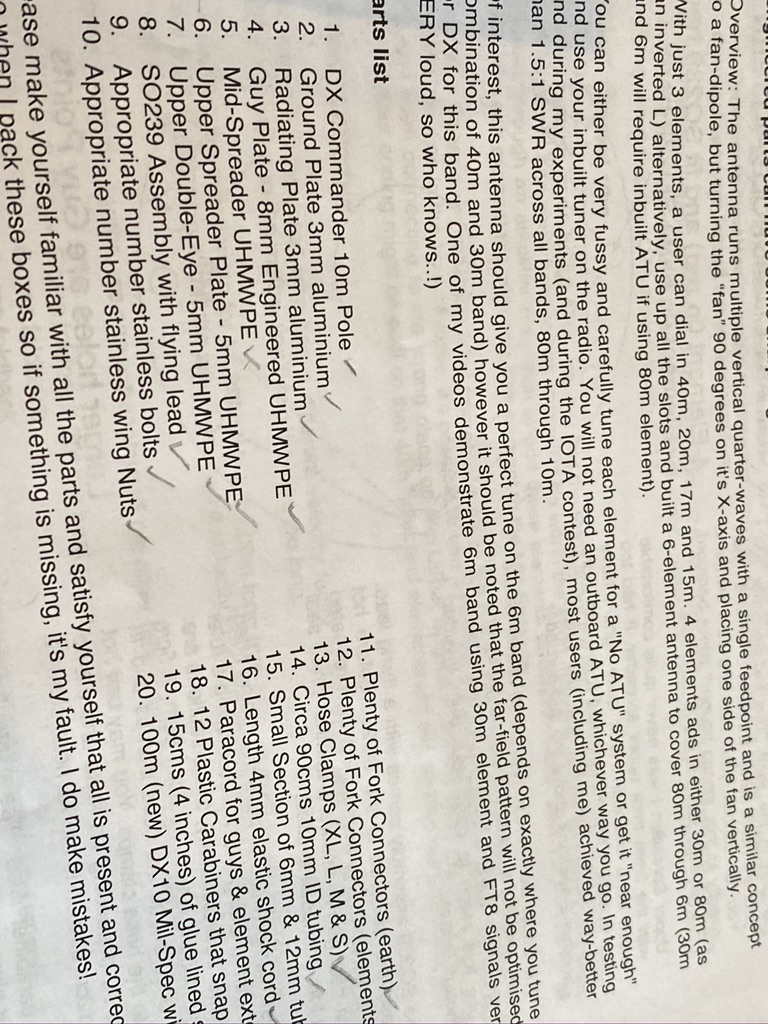

So its been a bank holiday here in the UK and its allowed me to work on quite a few different things (including re-wiring the Mazda Bongo door looms). When I got the DX Commander it came with enough wire for 4 verticals and the radials to support it, but I purchased some more wire from Radio World, namely the Watson Radio Products EQ Equipment Wire which goes for 40 per meter. I used Radio World as I had other bits and bobs coming from them as well, and my word, they are so QUICK to deliver (UPS Everything !).

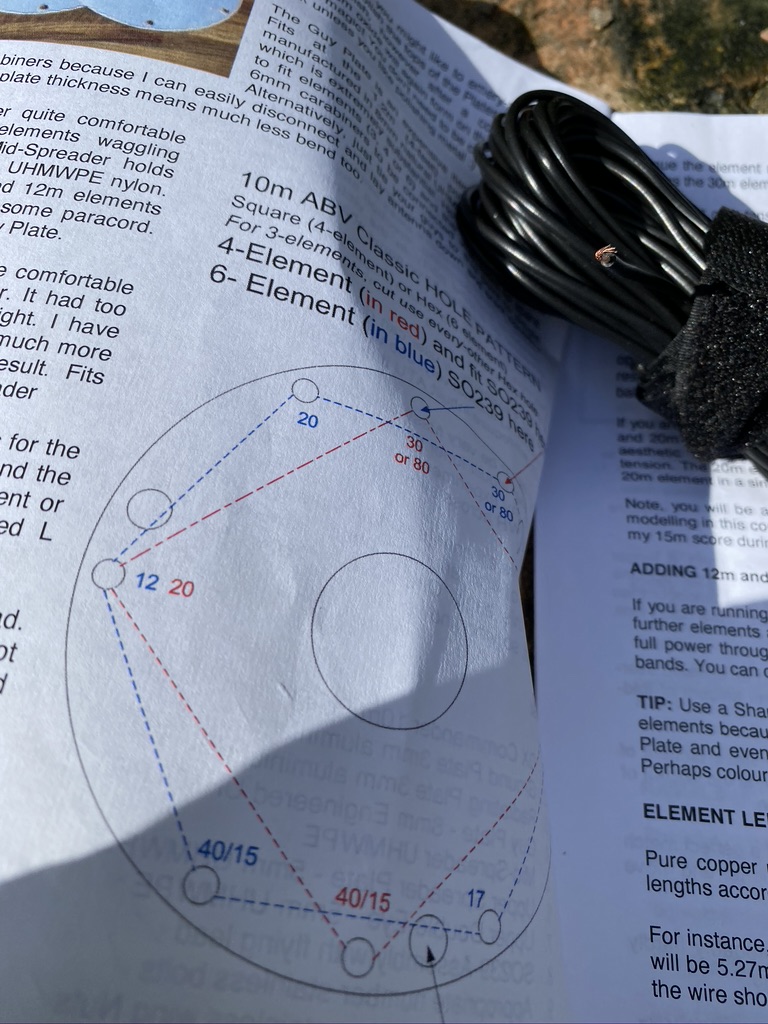

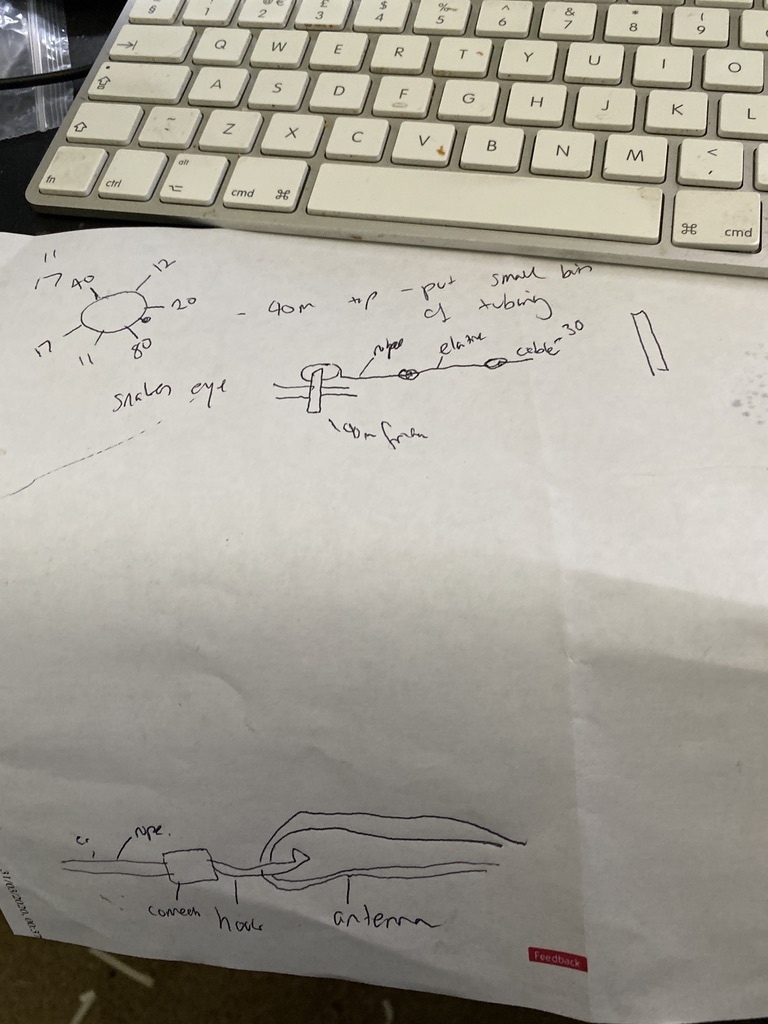

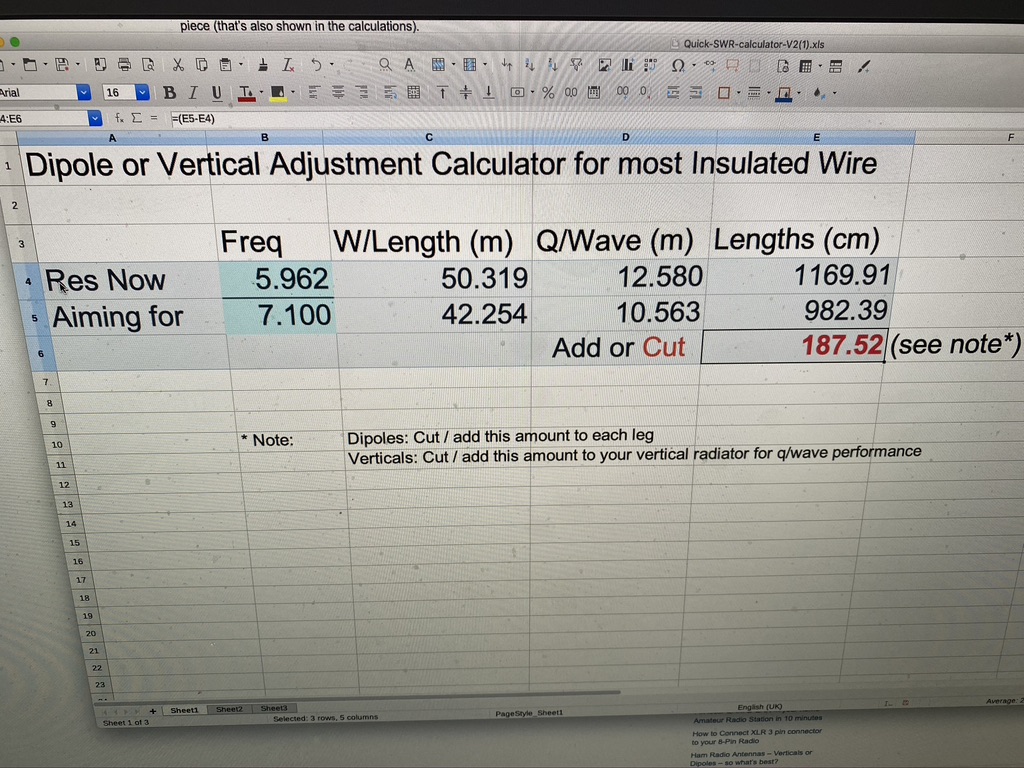

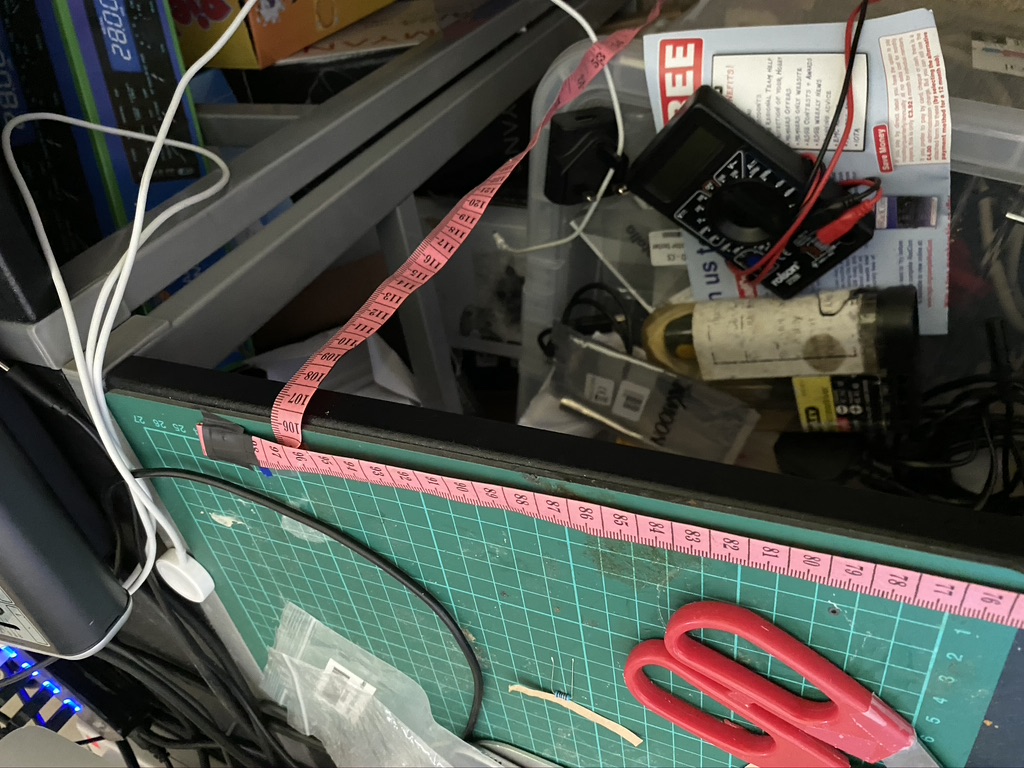

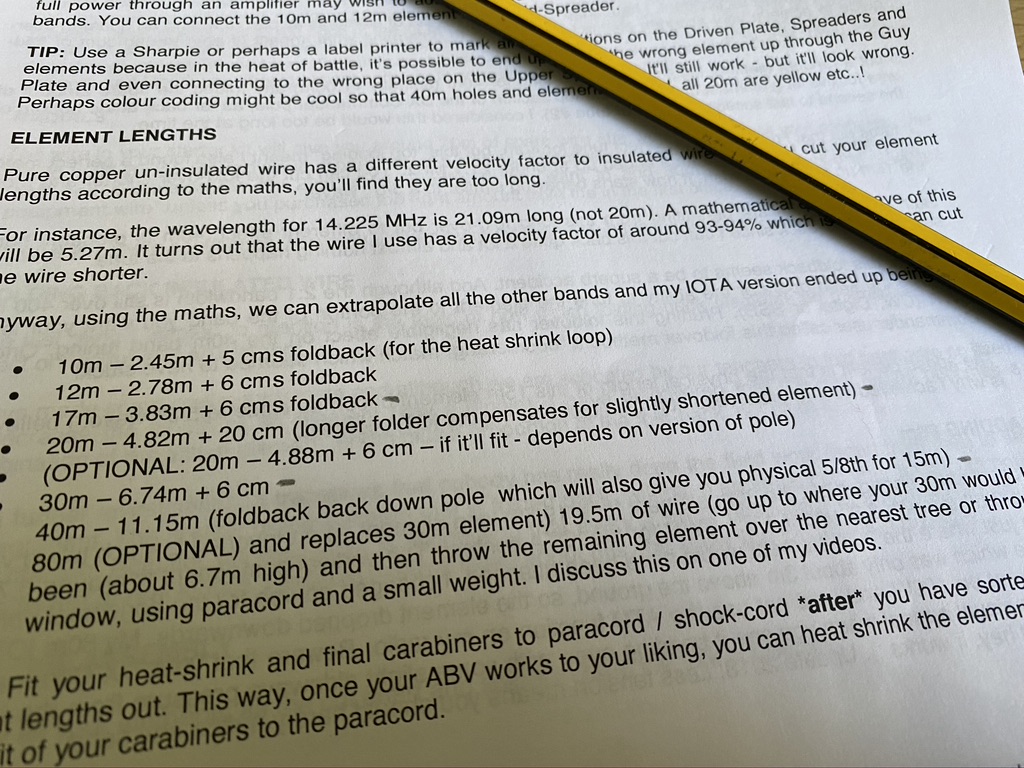

I checked from the list what additonal wires I would need to make up., in this case only the 10m and 12m. Having learned from trying to measure the wire indoors I now measure all my wire outside. I have 3 meter workmans metal tape which so far has done me brilliantly in getting accurate measurements.

| Wire (Frequency M) | Length to cut |

| 10m | 250cm |

| 12m | 284cm |

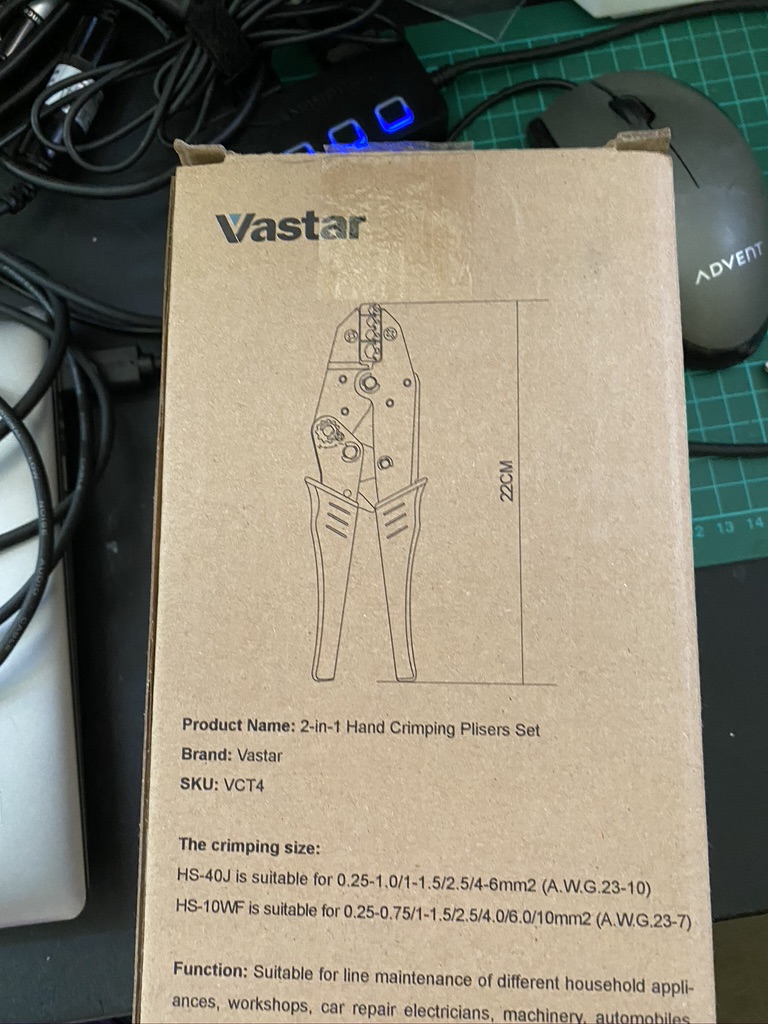

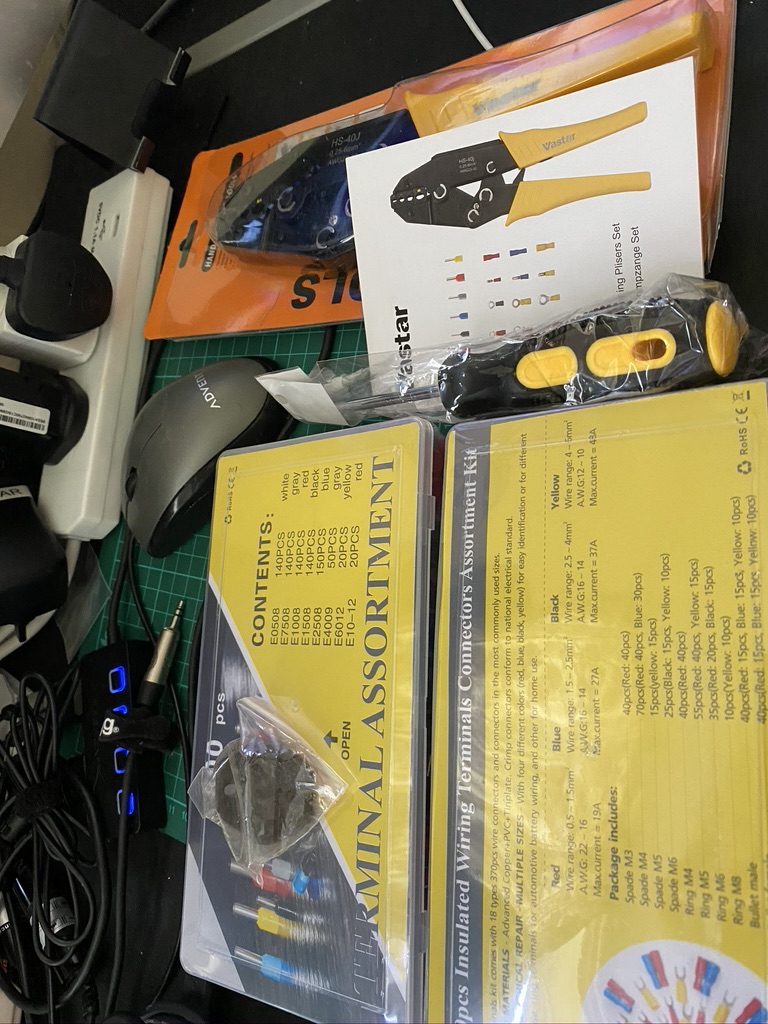

Having cut the cable I could set about using my new crimping tool I had got from Amazon, the Vastar 2 in 1 Insulated Ratcheting Wire Terminals Crimper (AWG23-10,AWG23-7. The reviews and price (£26.99)really hooked me, given how much just the connectors cost from Halfords.

nice message

a good sturdy box, will keep it in here

how it arrives, and how it shall live

really nice equipment

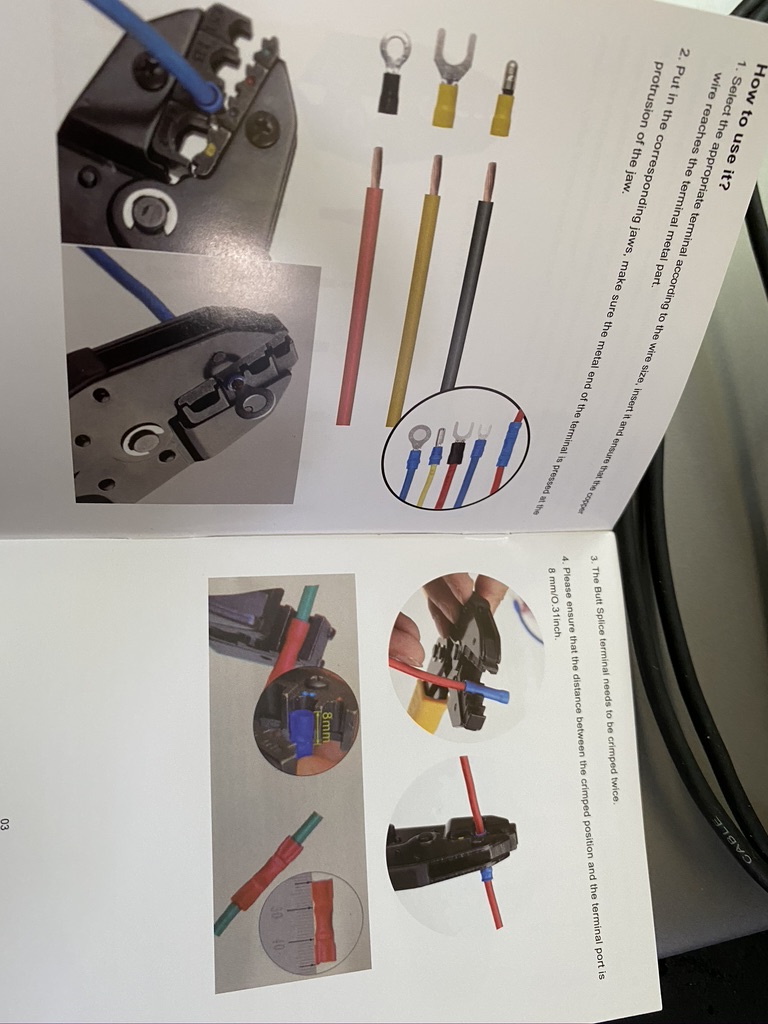

the user manual is clear as well

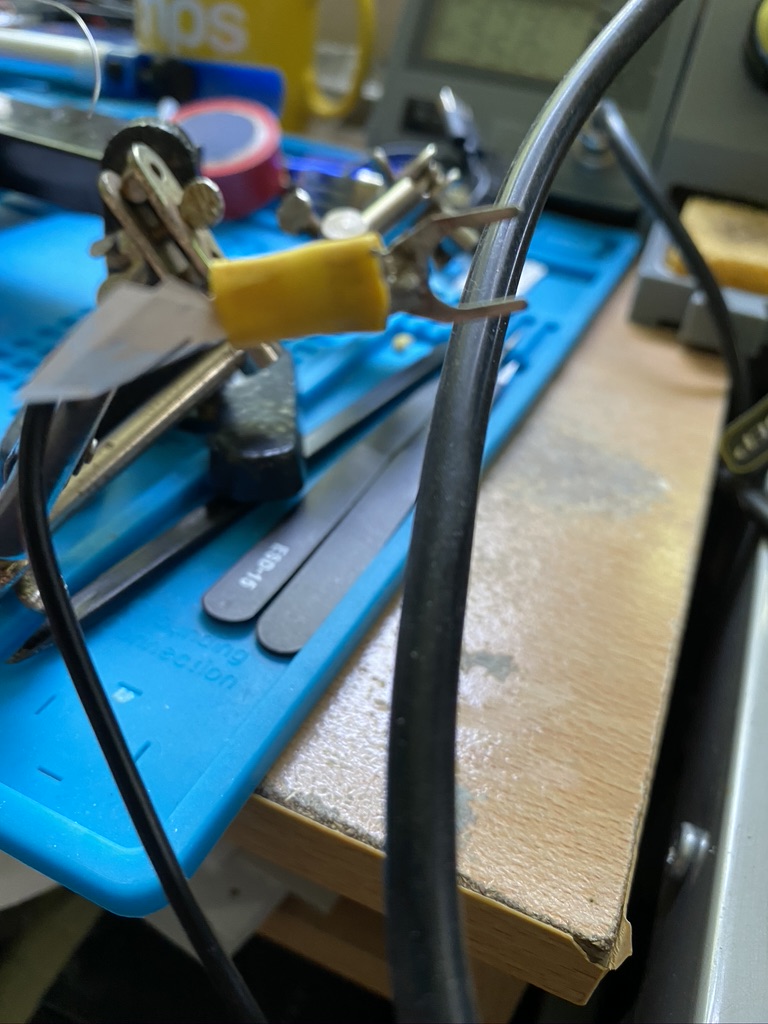

crimping away

wires – completed

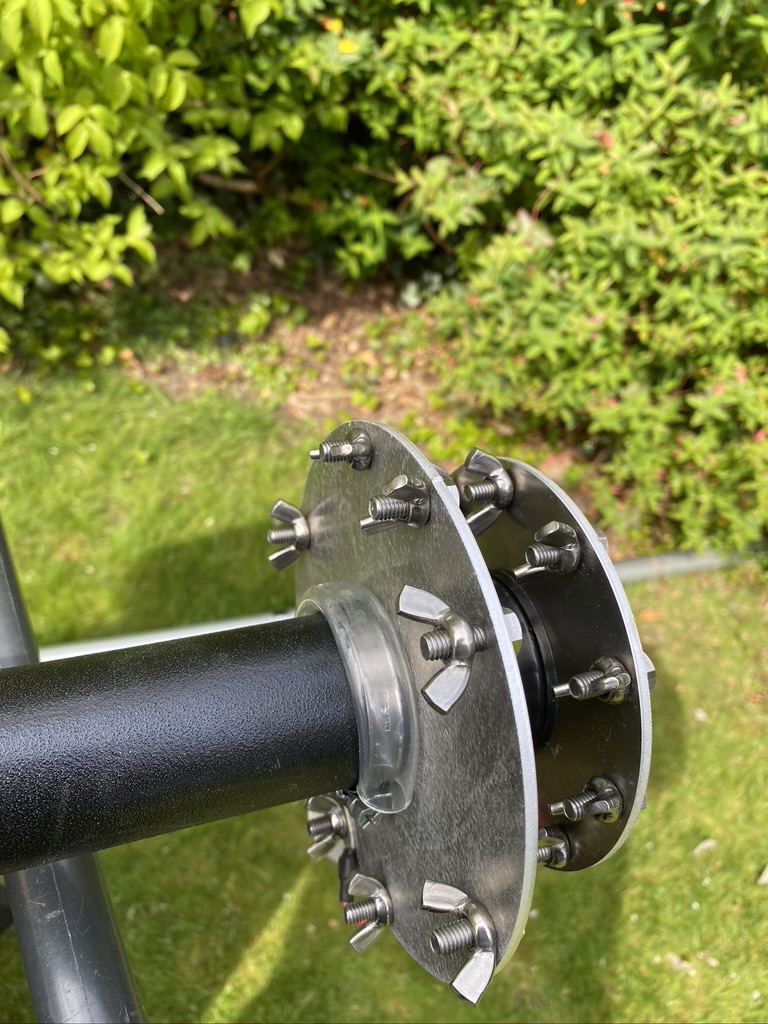

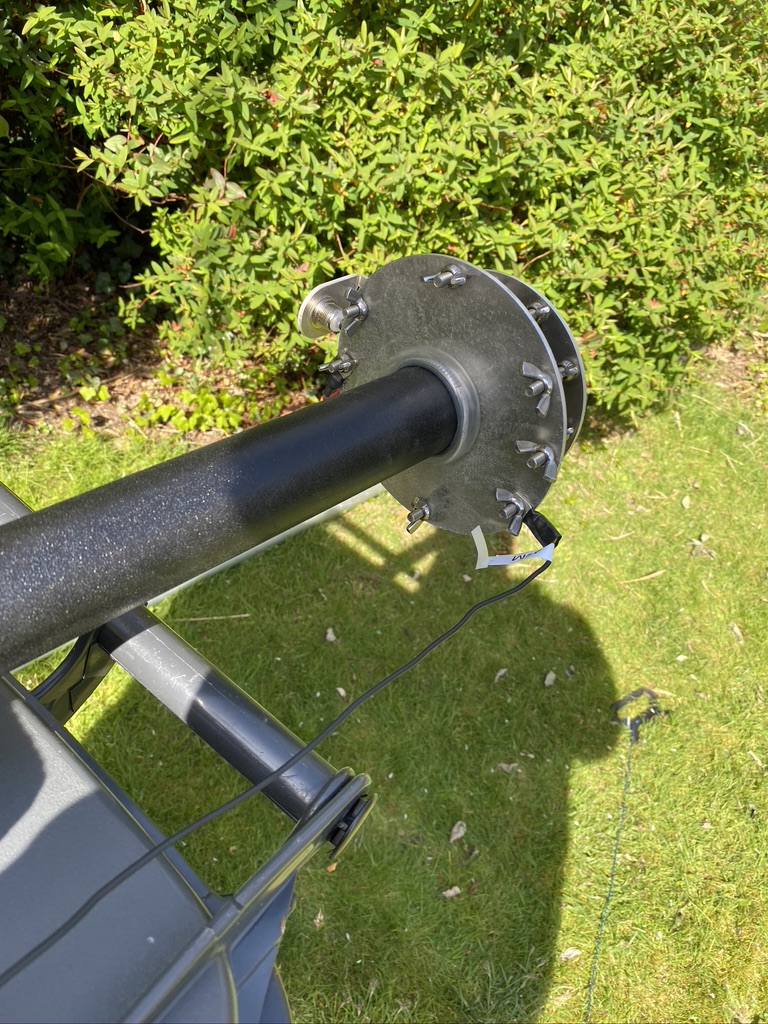

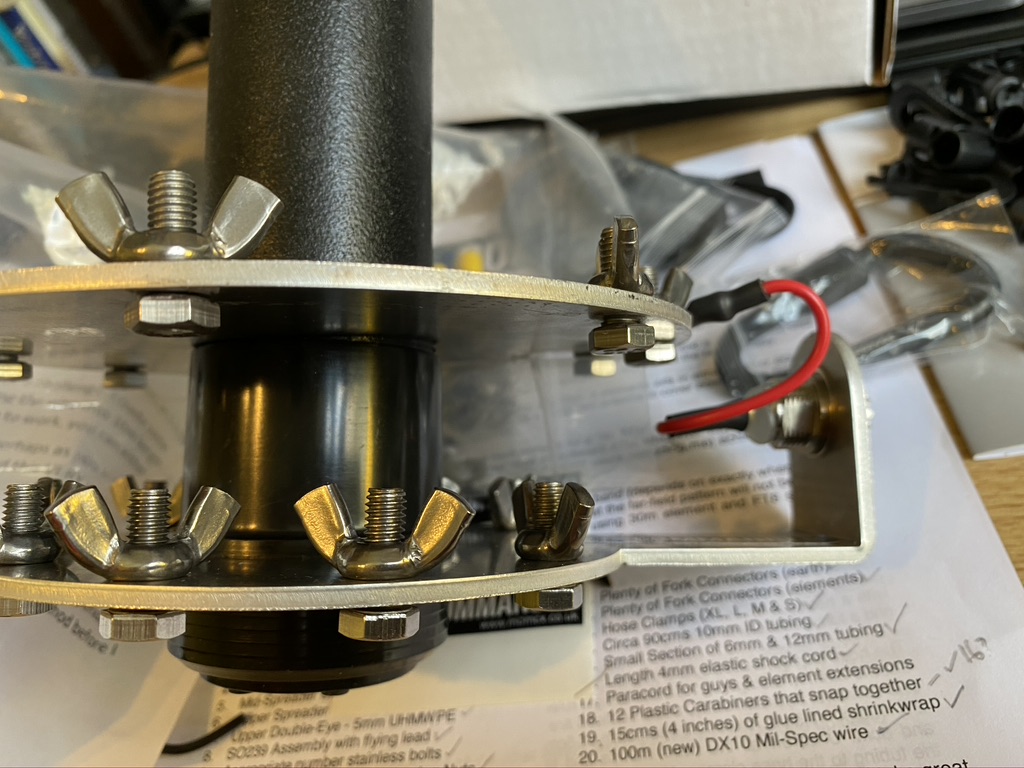

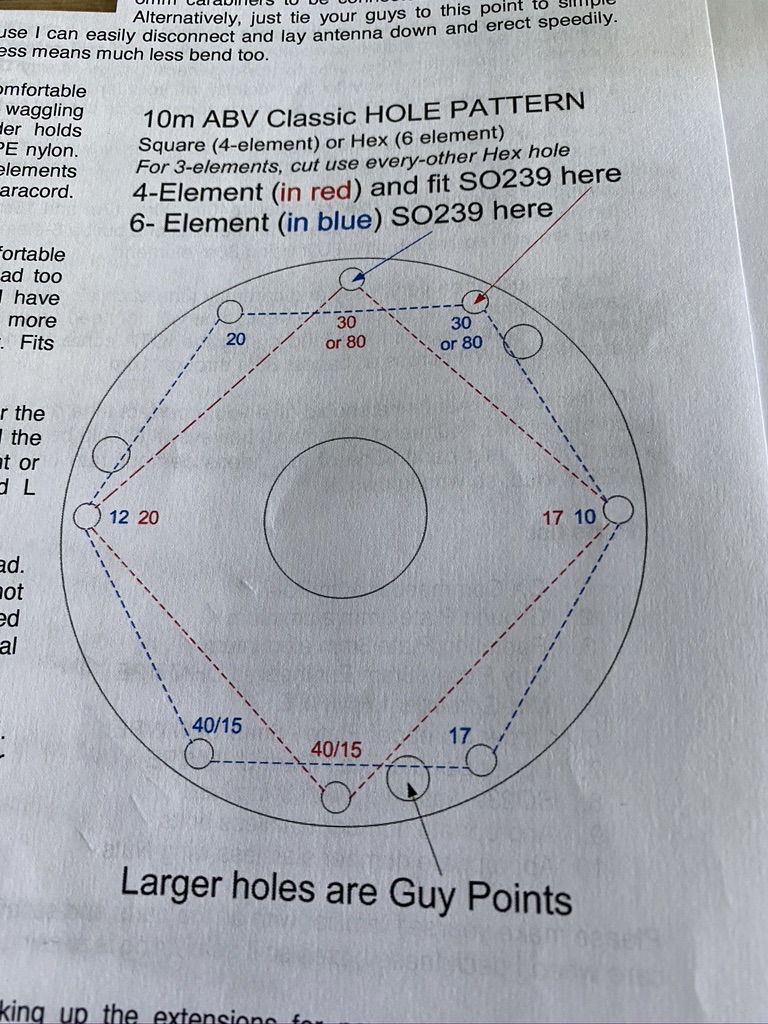

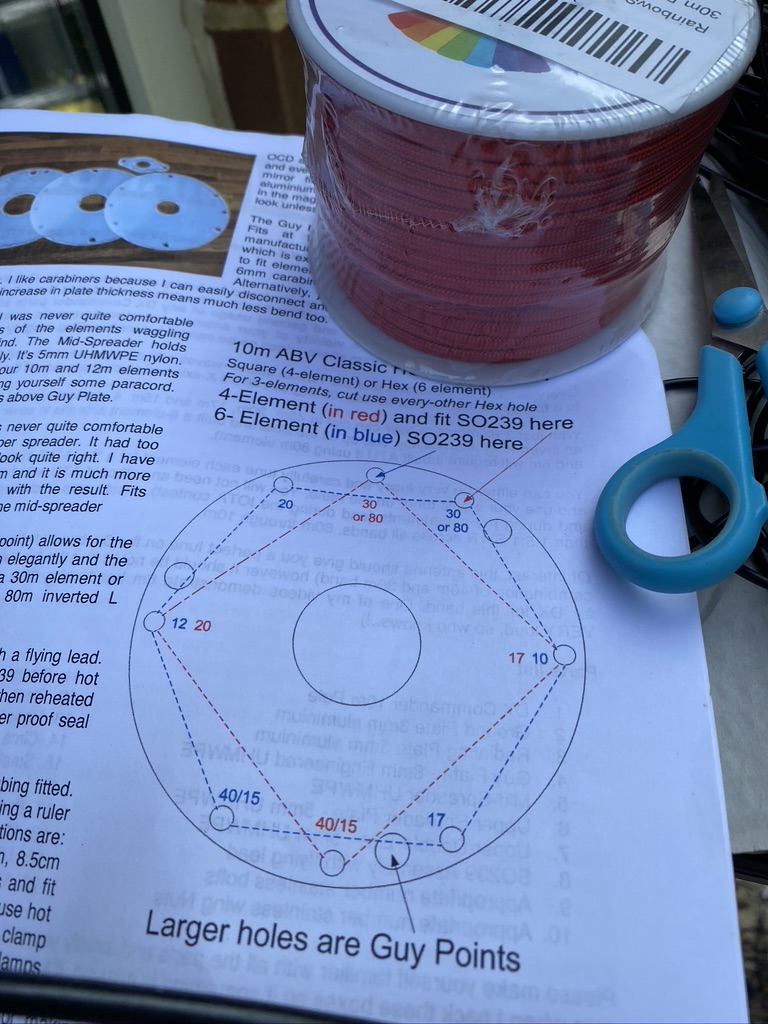

So the first part was to obviously lower the mast, and then remove the existing wires, Going from 4 to 6 requires adjustment as per DX Commanders docs (pg 2) here.

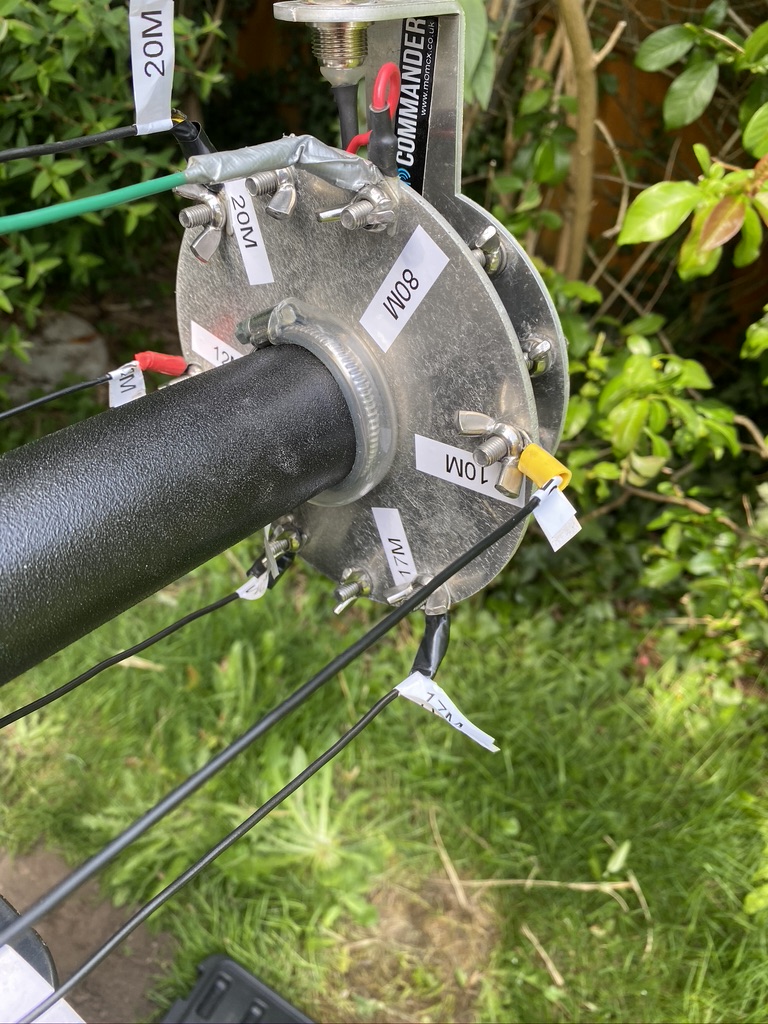

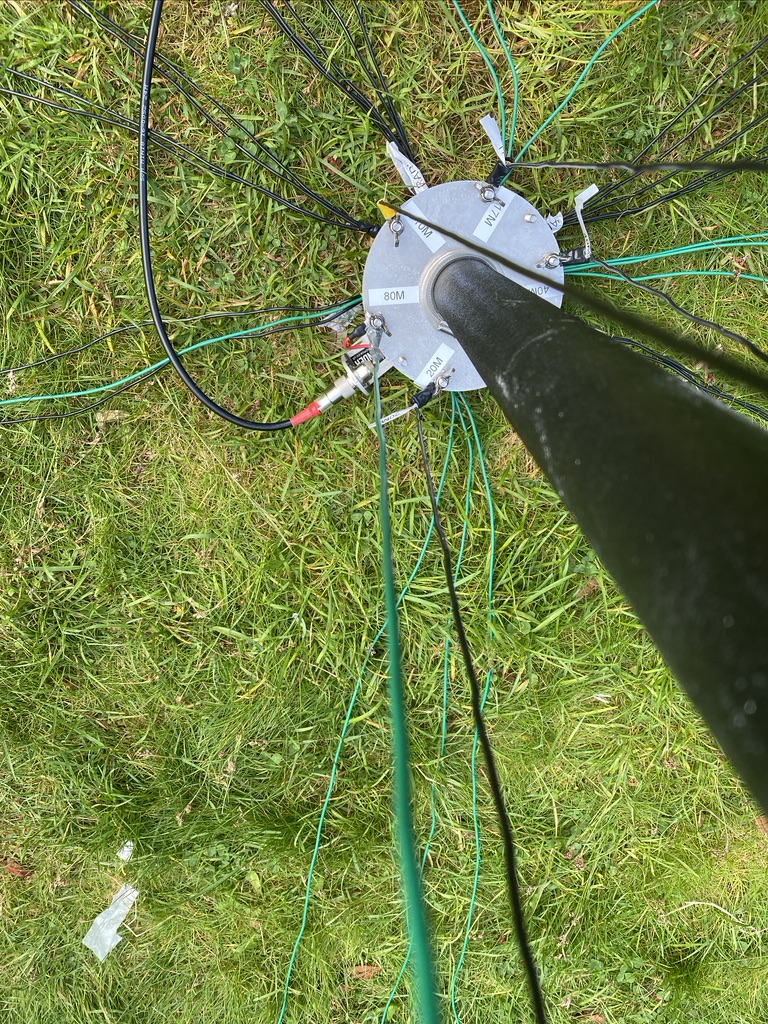

I also reprinted all new labels, removing the existing ones. One thing I didnt do orginally was to put labels on the bottom plate, so this time I would ! First I organized the cables so they was easy to pick up add, not having things on the floor and in a mess really adds to health and saftey when doing this kind of work.

With the mast lowered I followed the instructions and relocated the SO239 feed wire and the 80m connection

What really helps is the DX Commander stickers. On my spreaders i do them so that they should be aligned when looking down the mast, this gives me a good point of reference.

To start with I just feed the 80m wire up to where it would be for 30m and taped it down. I then worked around the mast feeder positions adding labels as I worked in each new wire.

its not just a great little radio

its a box for all the stickers!

Now the DX Commander/Calum does say that the clips used on the paracord are hard to undo once set, as I found. Having to try and extract one, manage to break a clip, and I had no spares. So, i thought, well superglue it is then ! With using the YOCTOSUN Hands Free Magnifier, i was able to get it to glue pretty much back on. I was then with the existing cut paracorde and elastic cable to add the other elements which required some vertical tensile strength.

repaired clip holding out

loopbacks doing their job

some additonal ‘temp’ fixes

12m, tied directly to the lower guide/spreader

I continued to add all the elements and was happy with the tension and how tidy they are. I also took some time to put some tape around the clips where sometimes the wind will blow and wires get caught in the juberliee clips. As I’m not taking the mast down and collapsing, this wont effect me in the short-term.

nicely labeled plate

tidy going up

some ‘fettling’ with tape for now

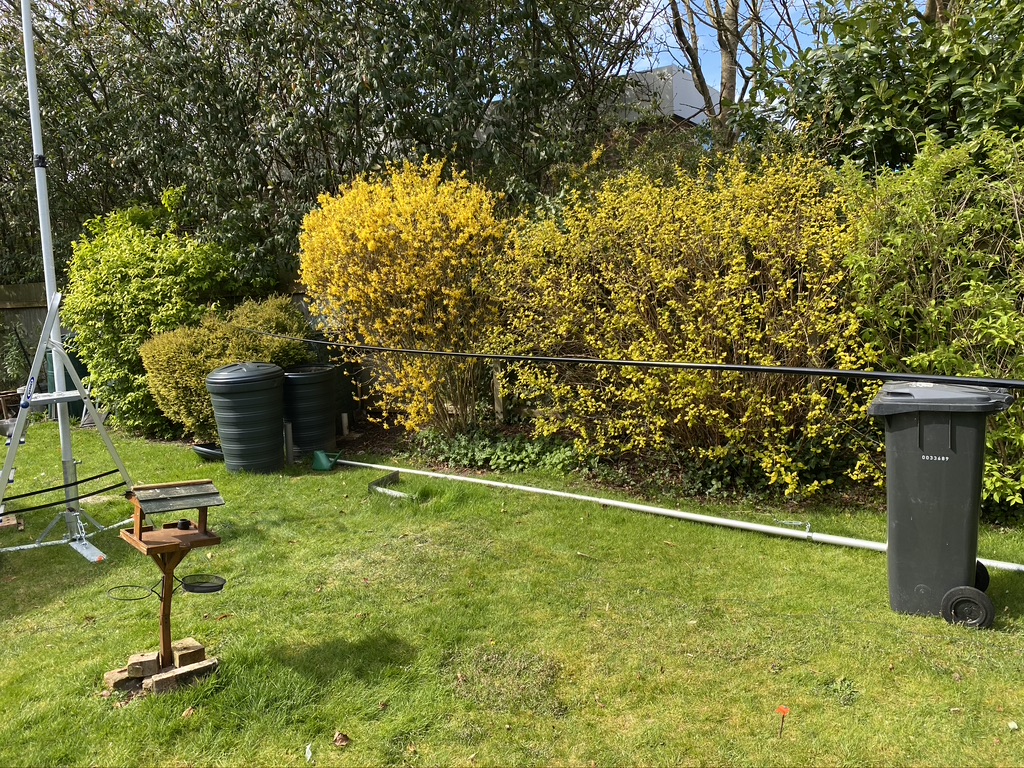

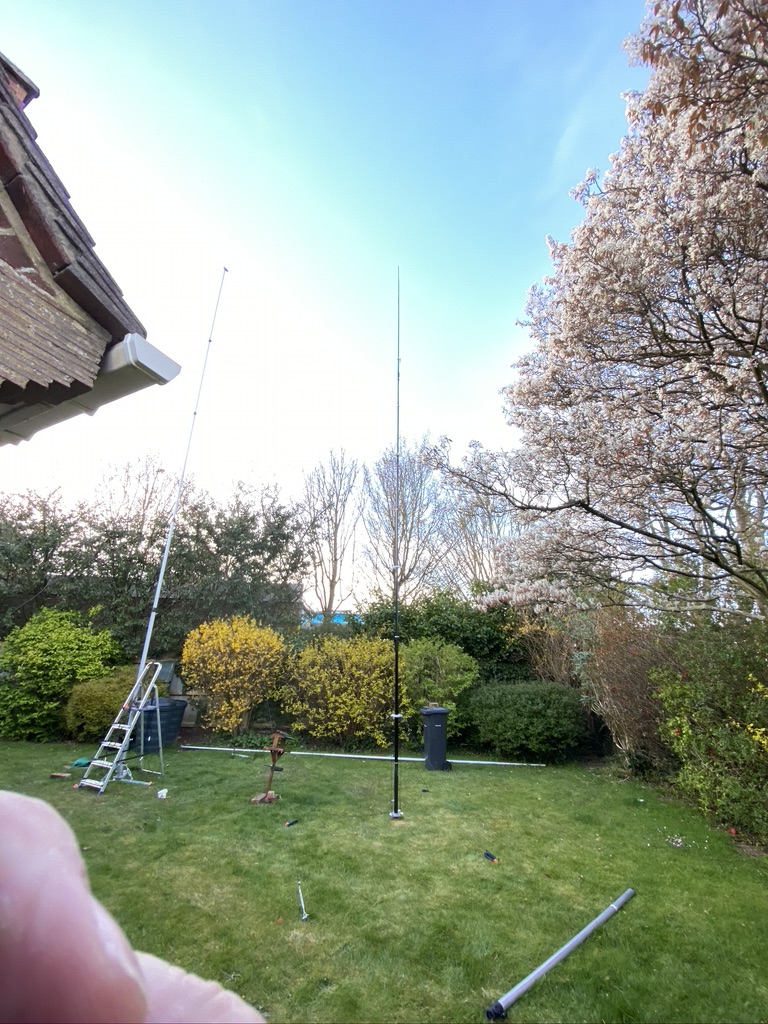

With assistance from my son, we got the mast vertical and I could start adding the existing radials I have. I add the radials in a N/E/S/W layout starting from the feed point, and adding where i have capacity. I also done a ground-visual of the 2m/70cm with my iphone (10x max zoom) and could see it was in good shape up there after I had raised it on Friday.

approx 28-30 radials

spreading them out i go N/E/S/W, then fill the gaps

A quick visual on 2m/70cm antenna

Testing and Results

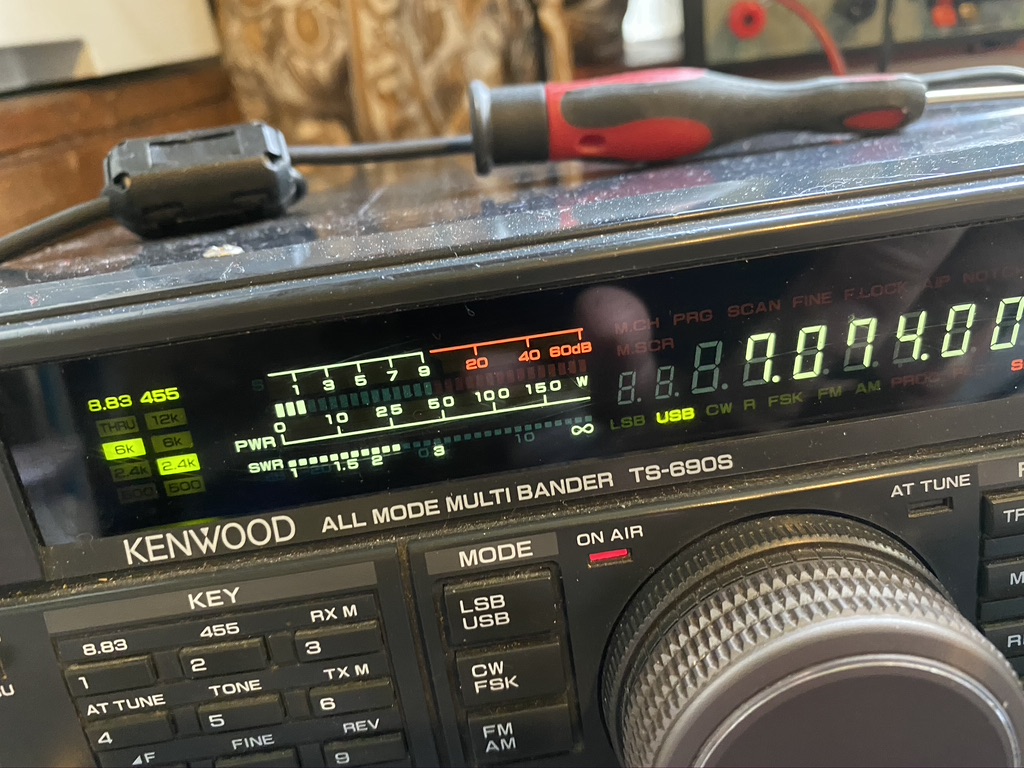

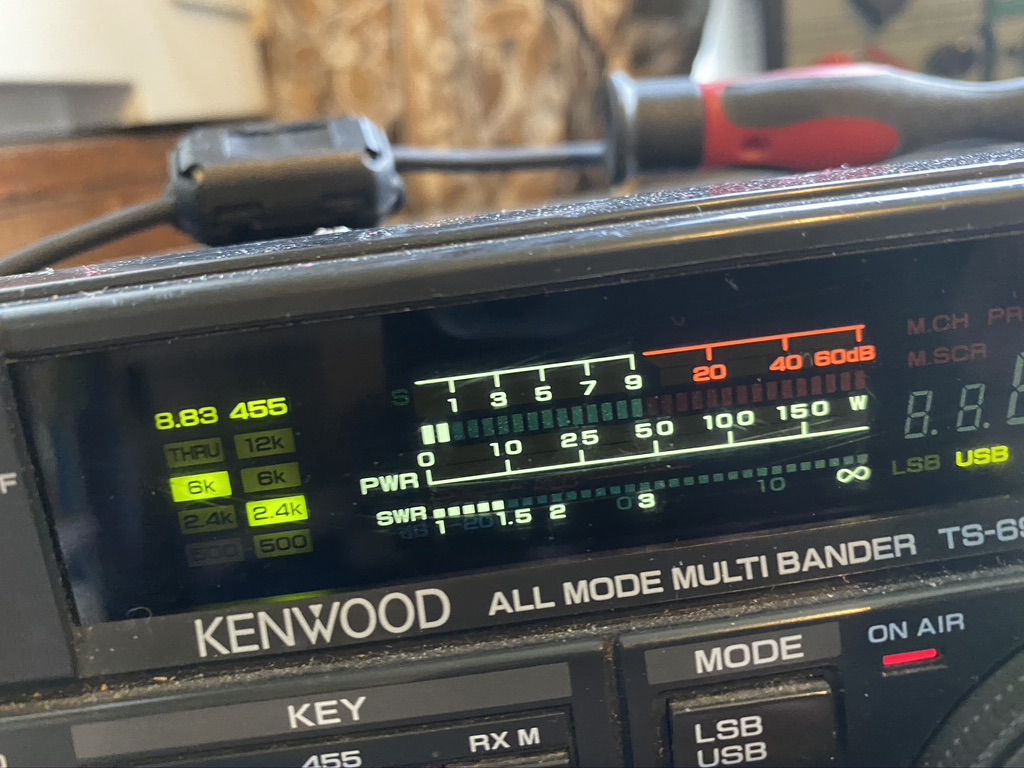

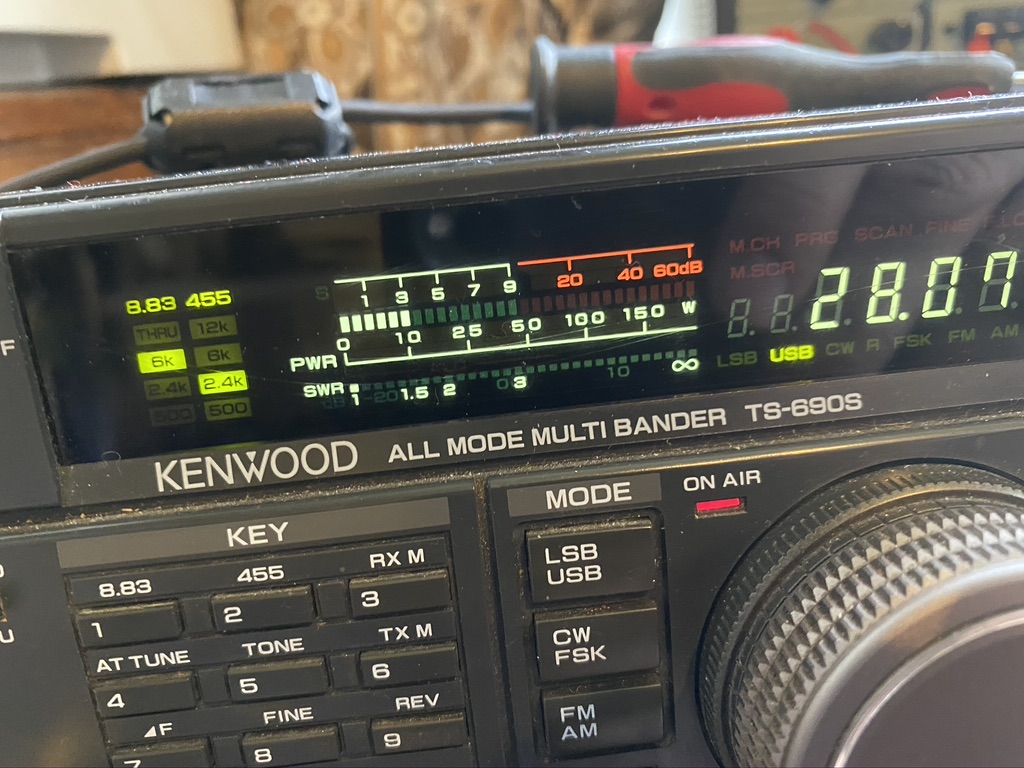

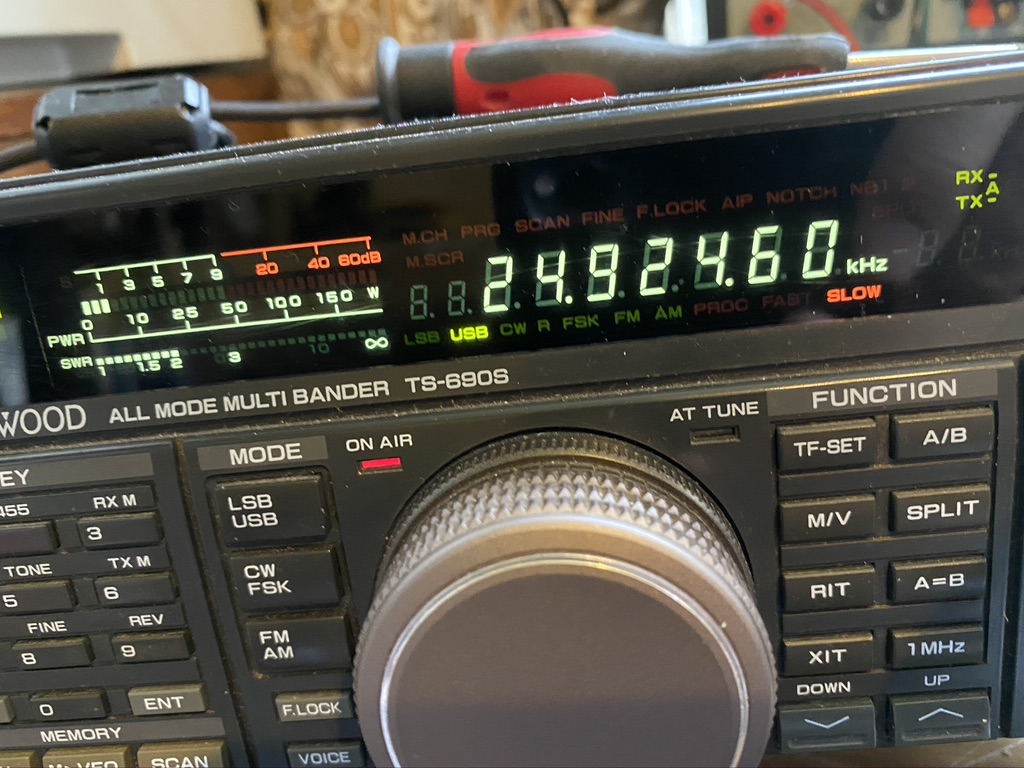

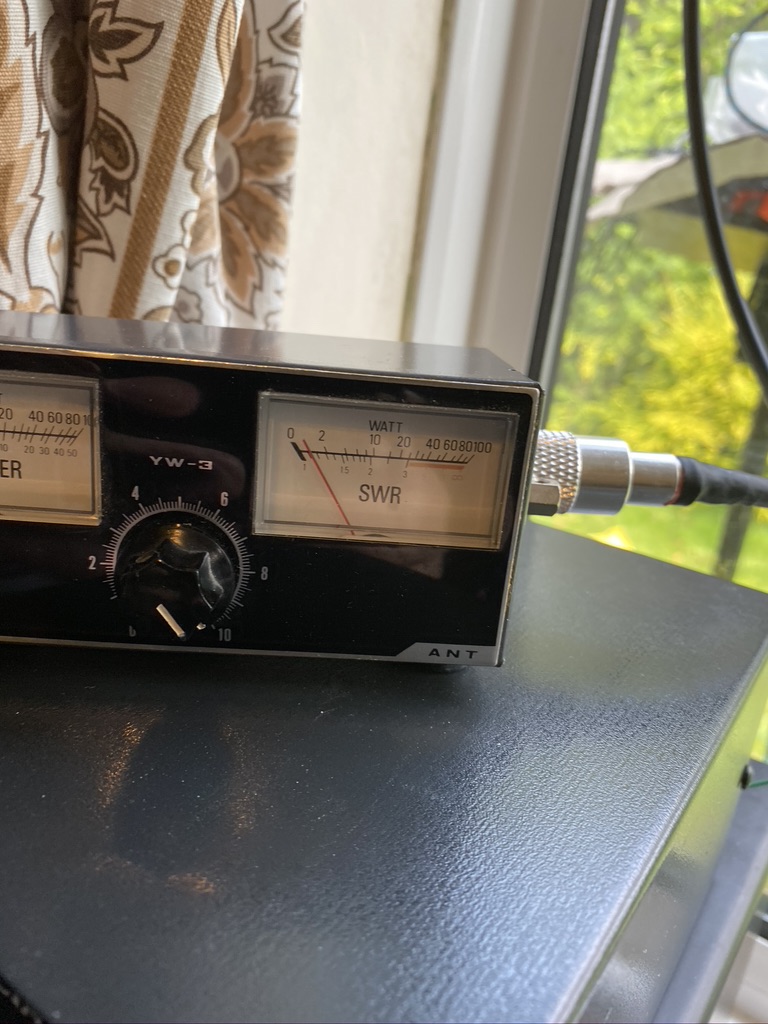

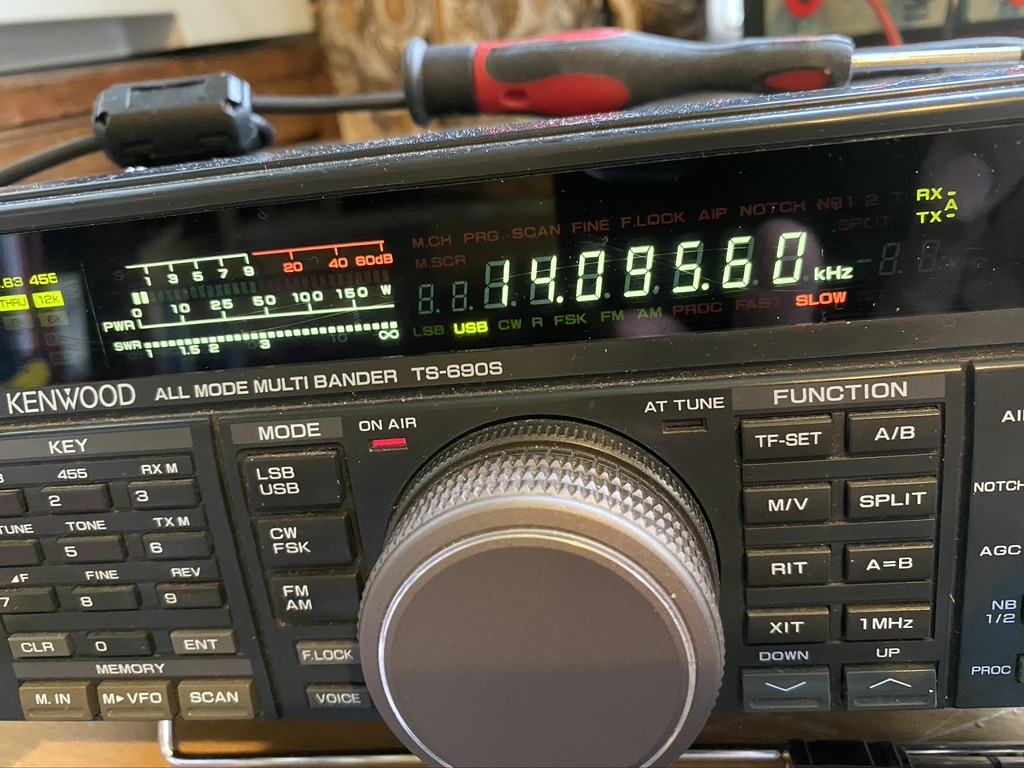

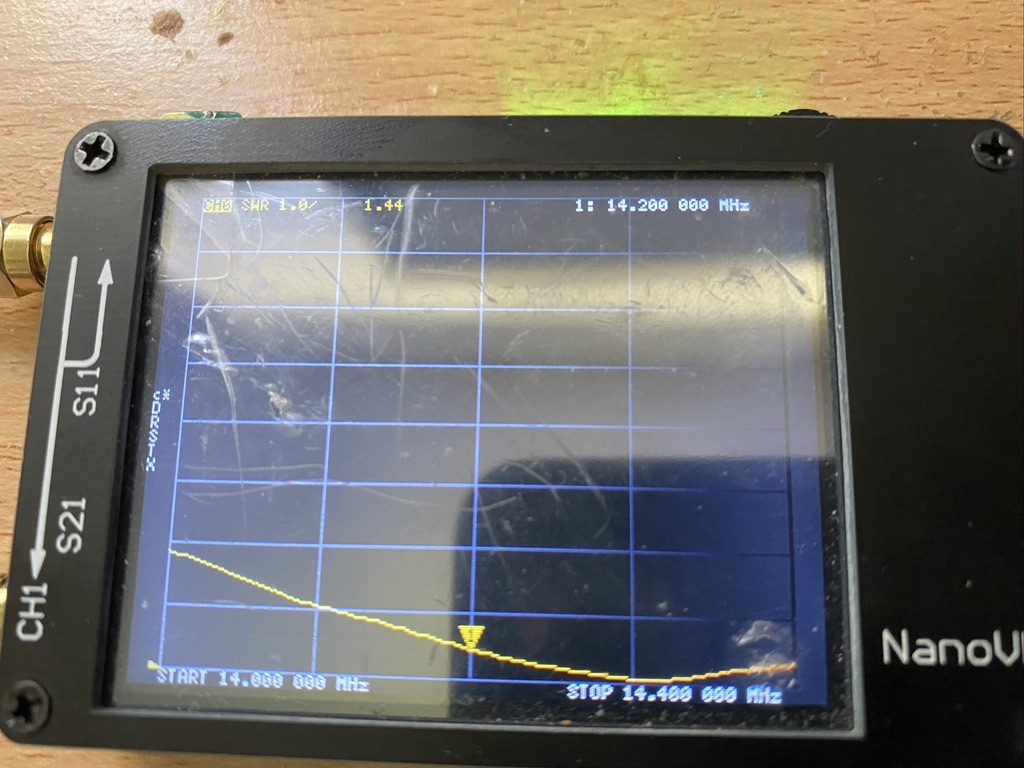

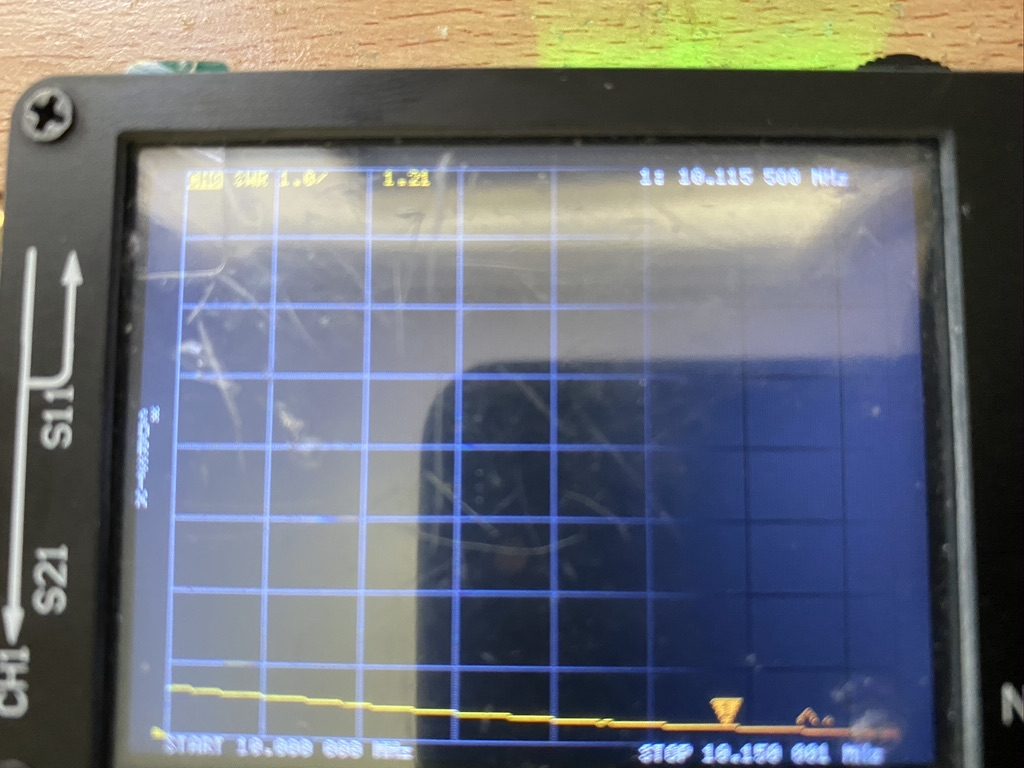

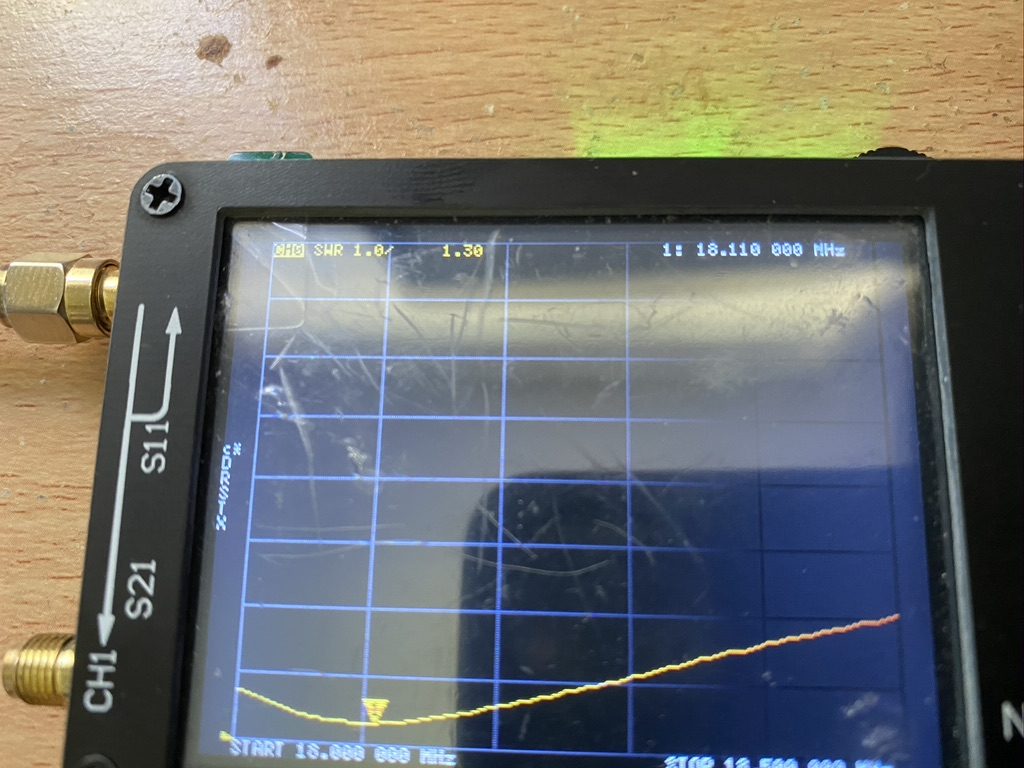

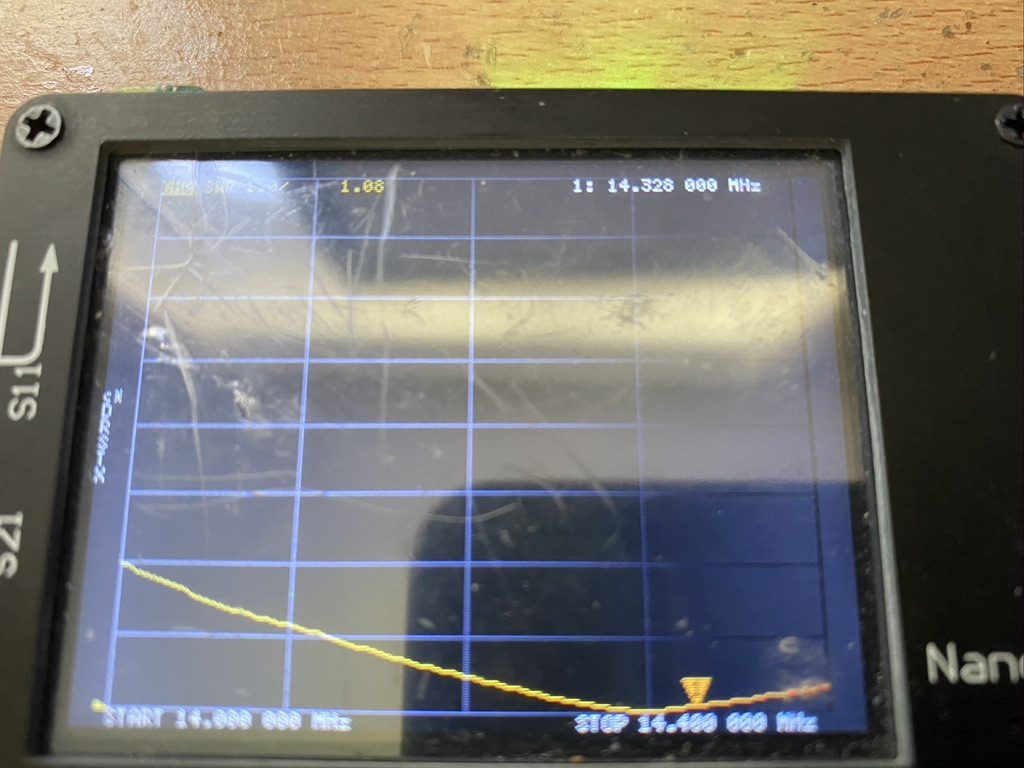

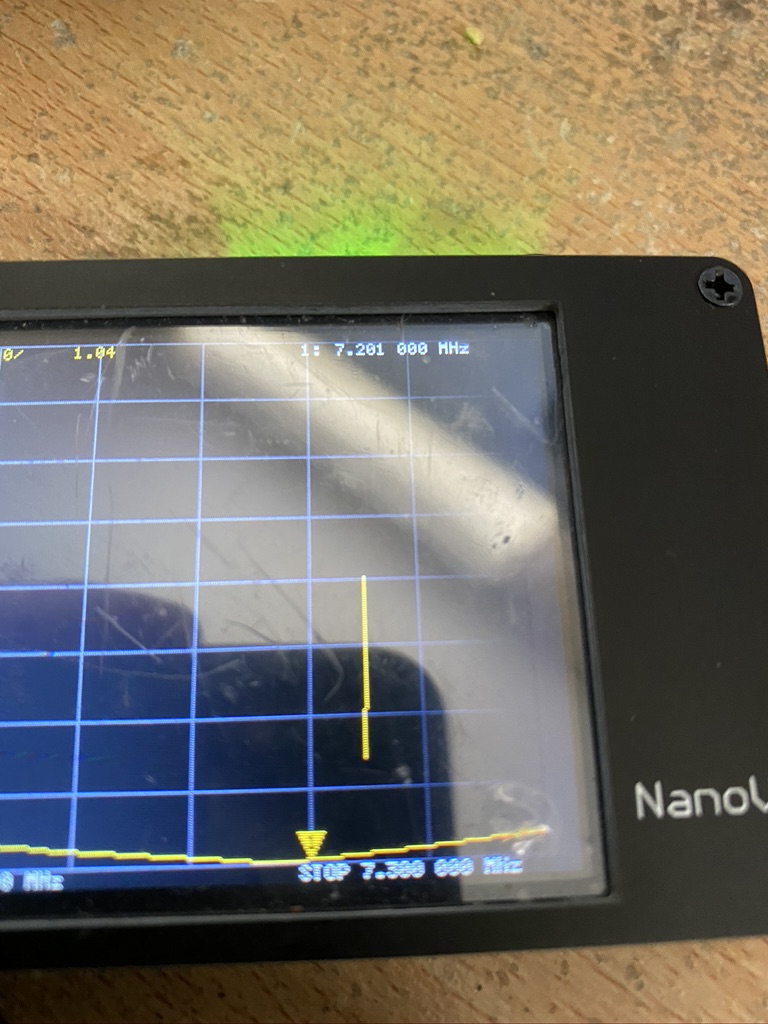

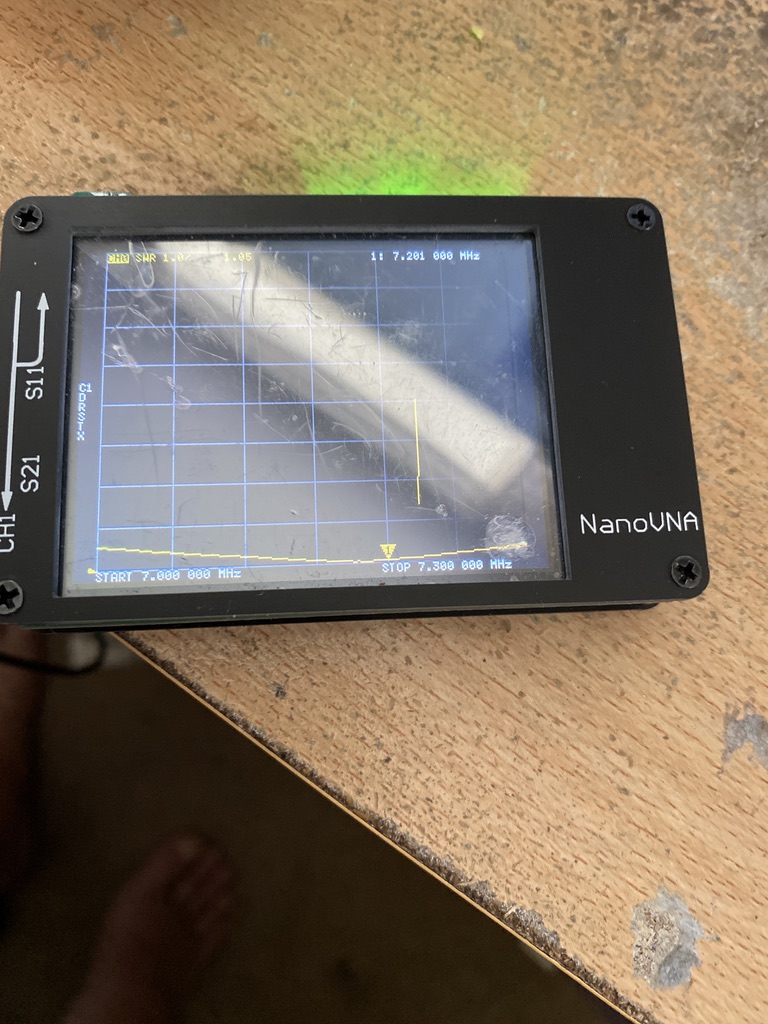

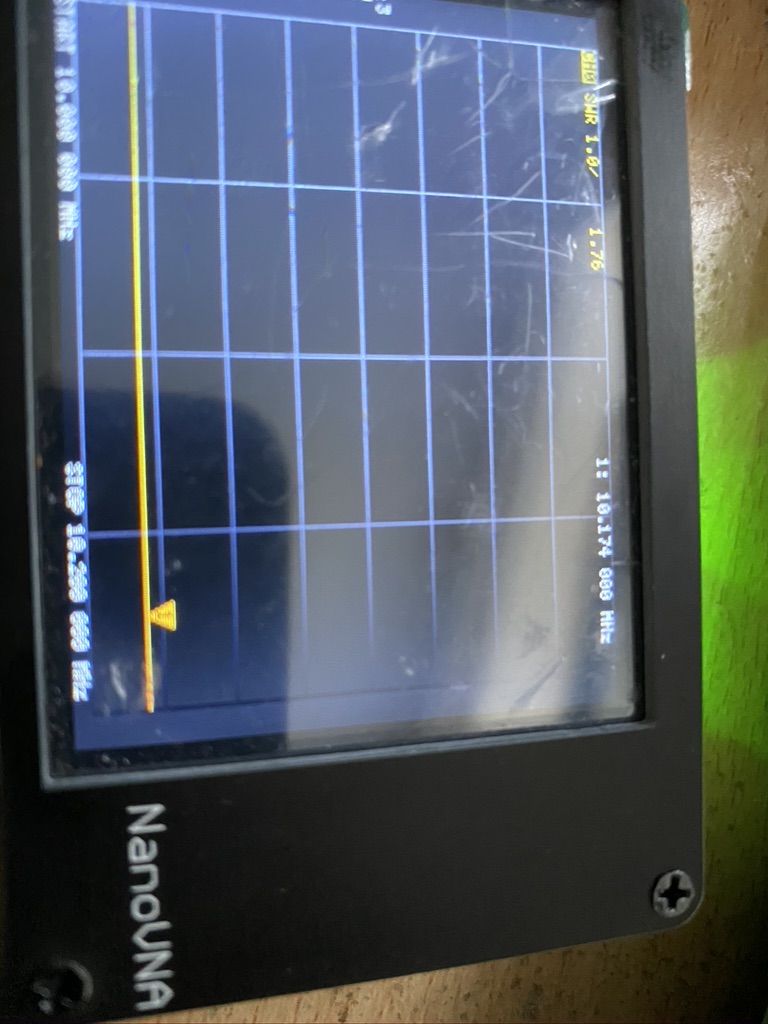

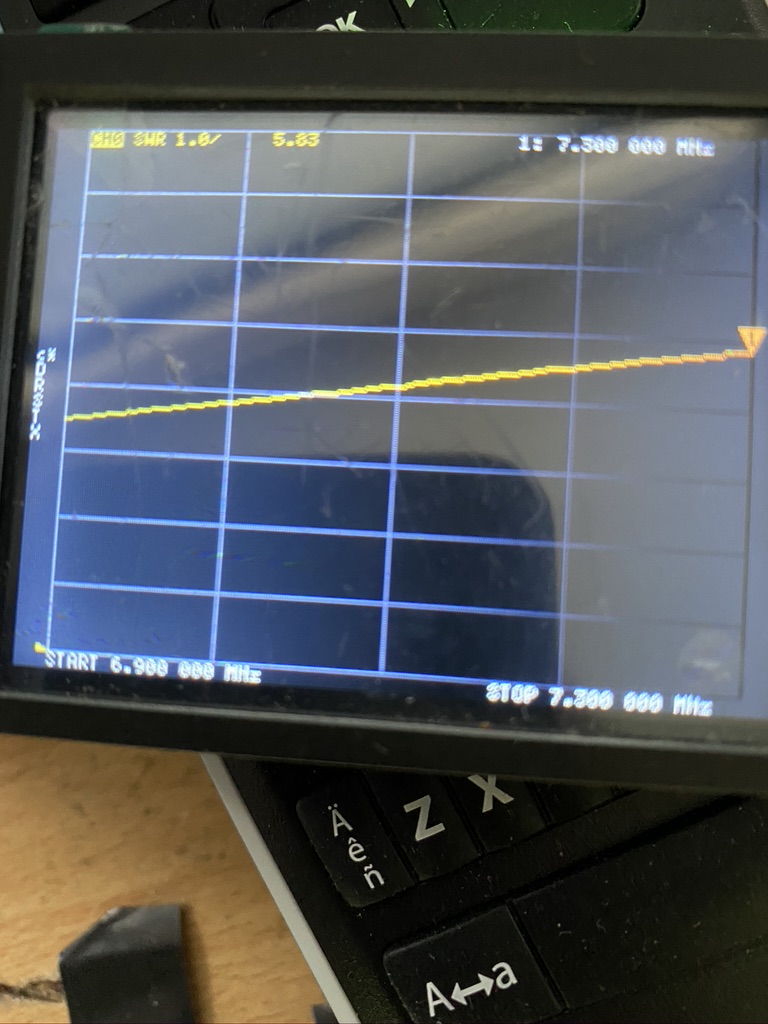

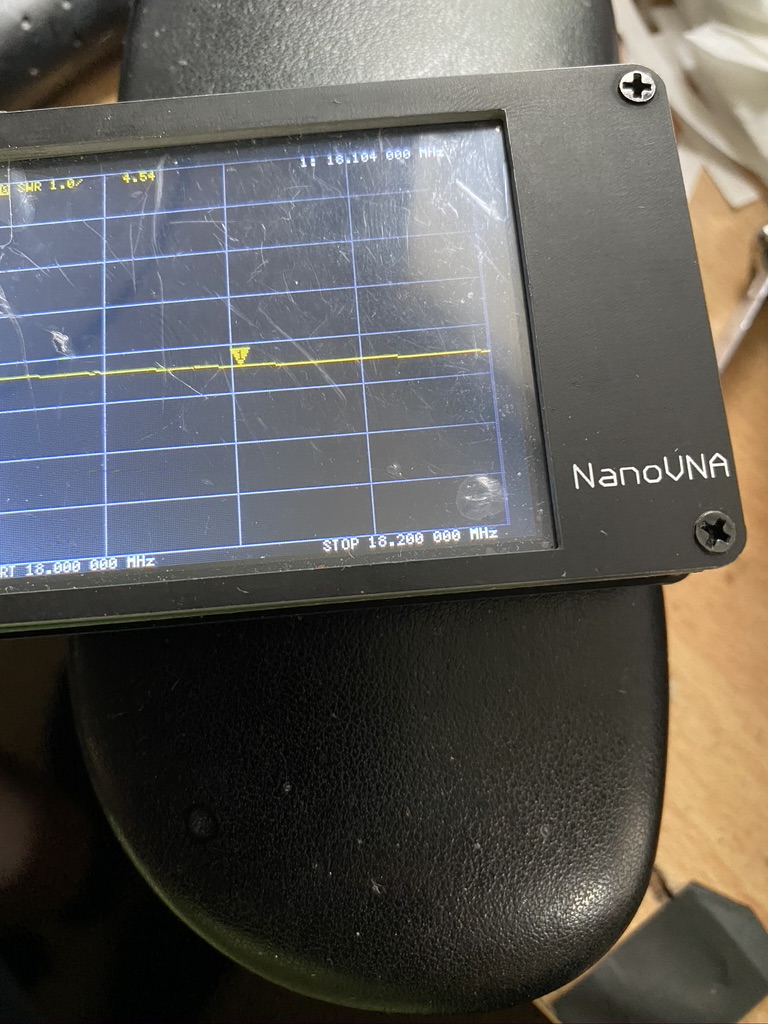

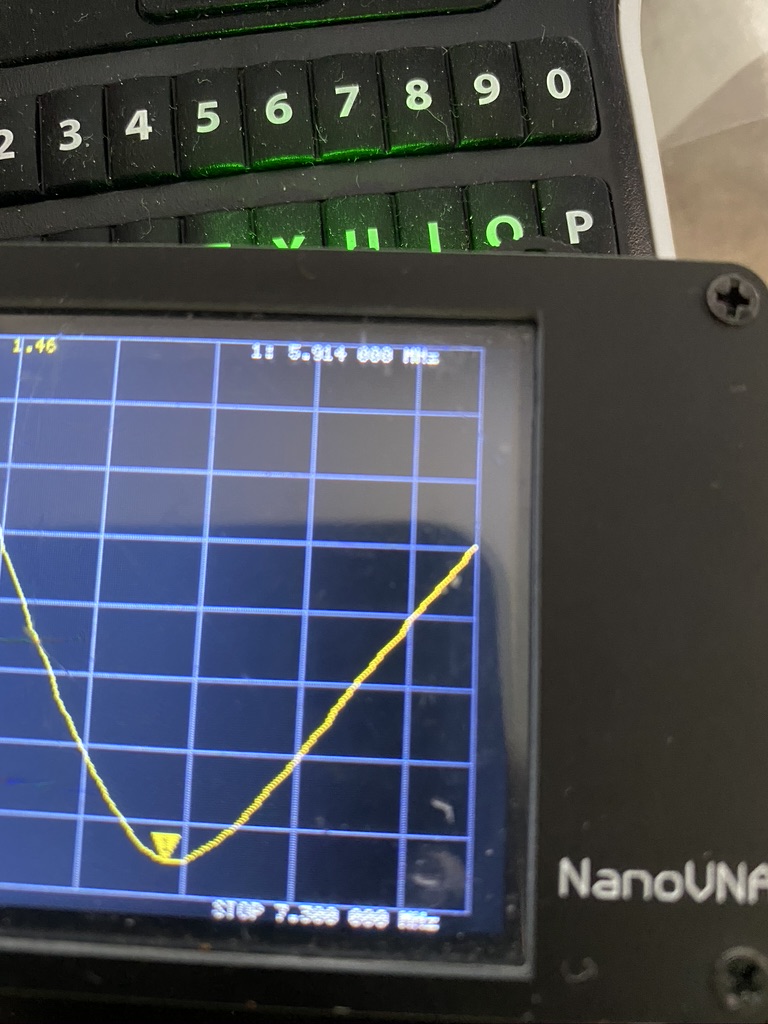

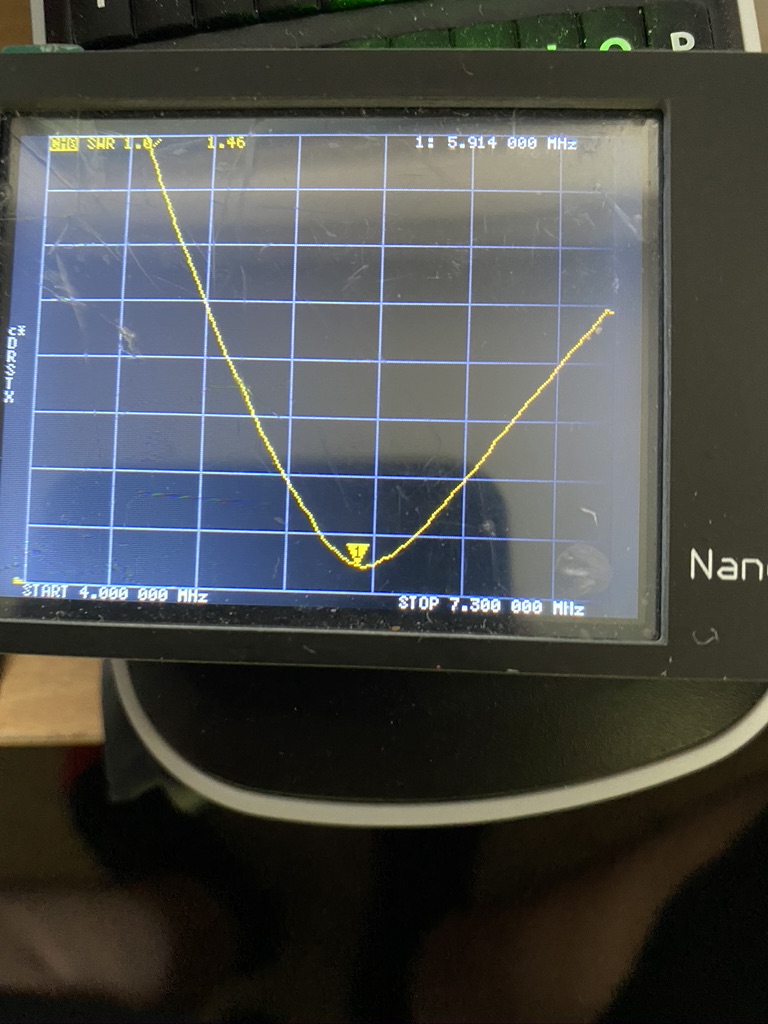

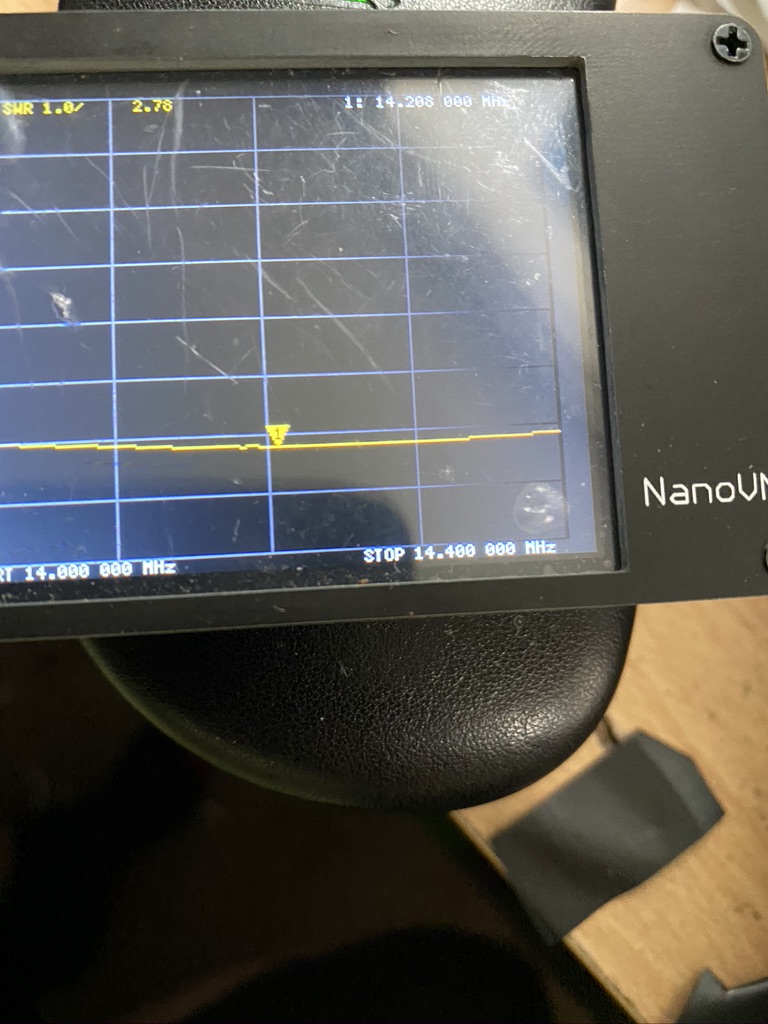

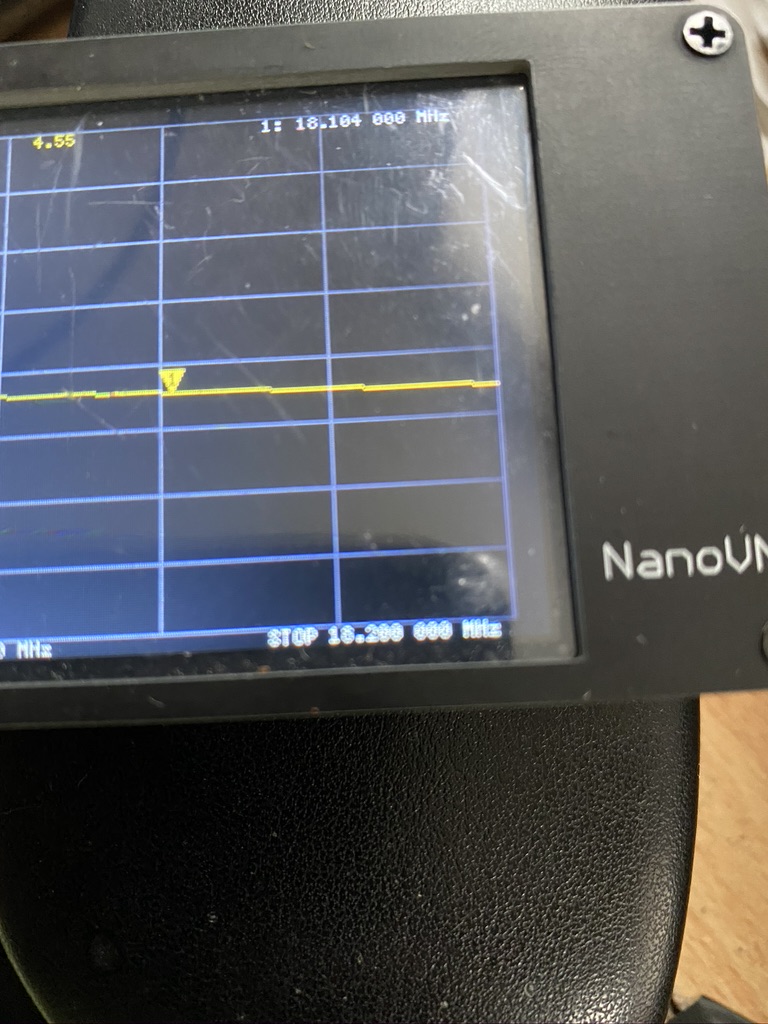

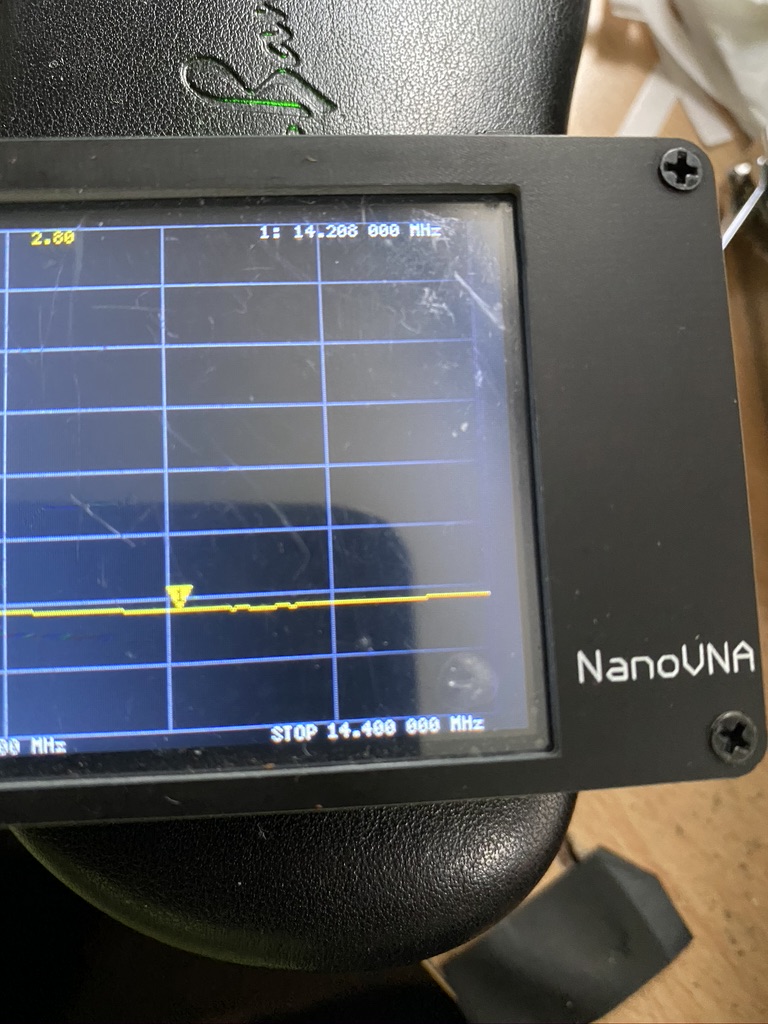

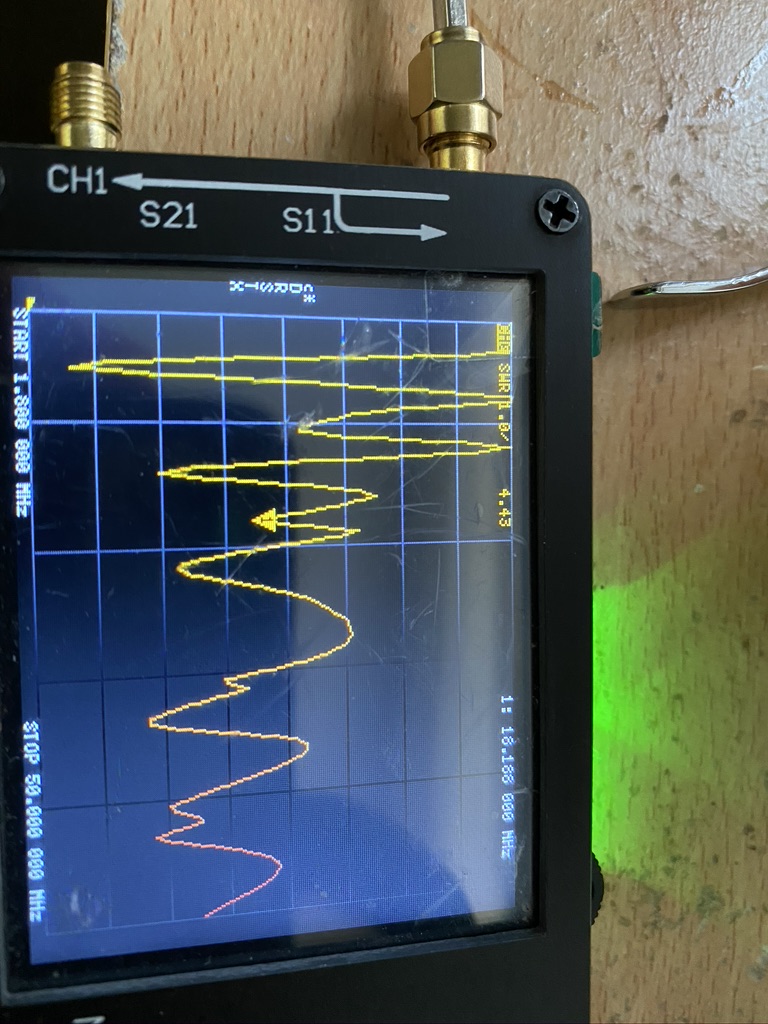

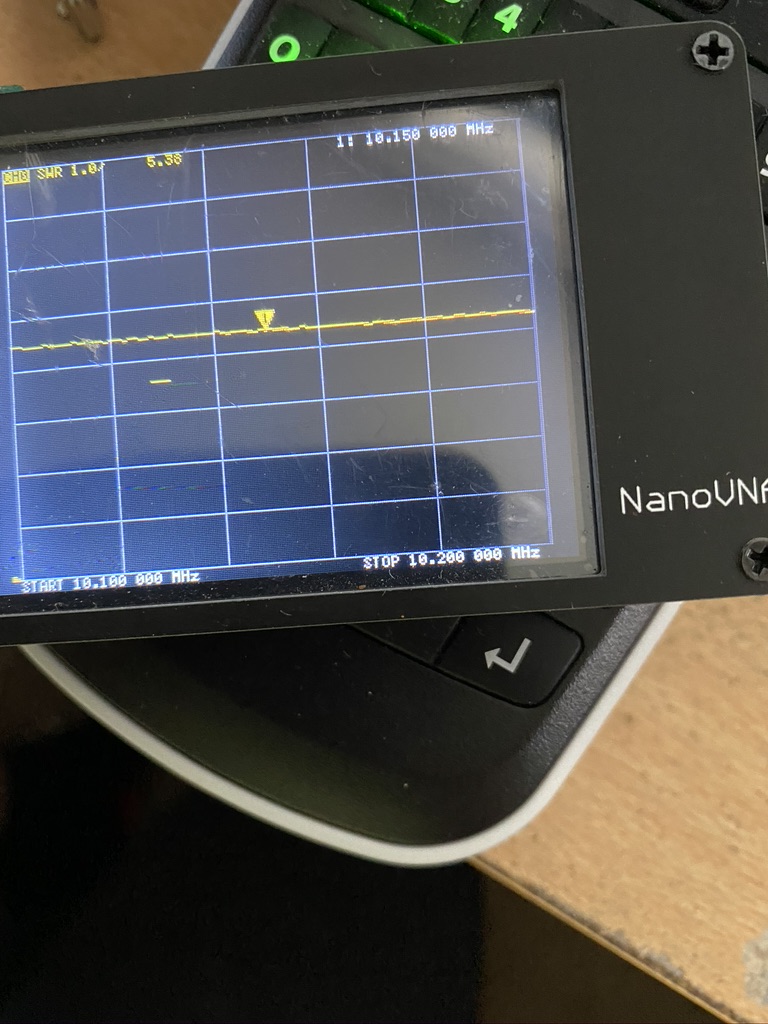

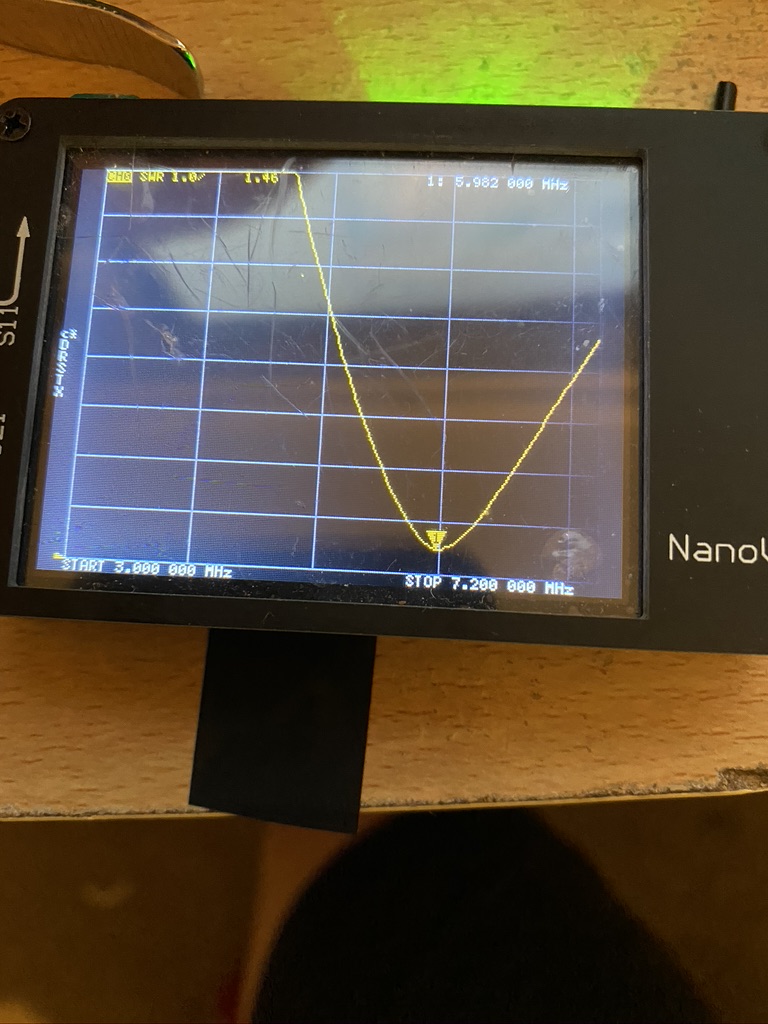

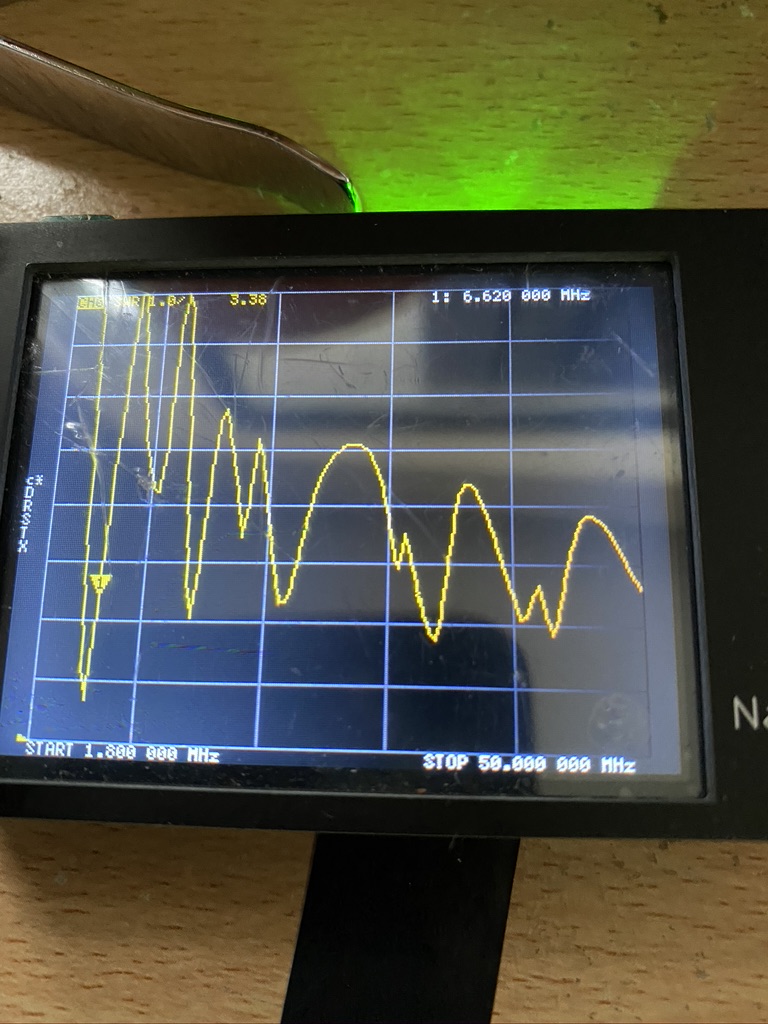

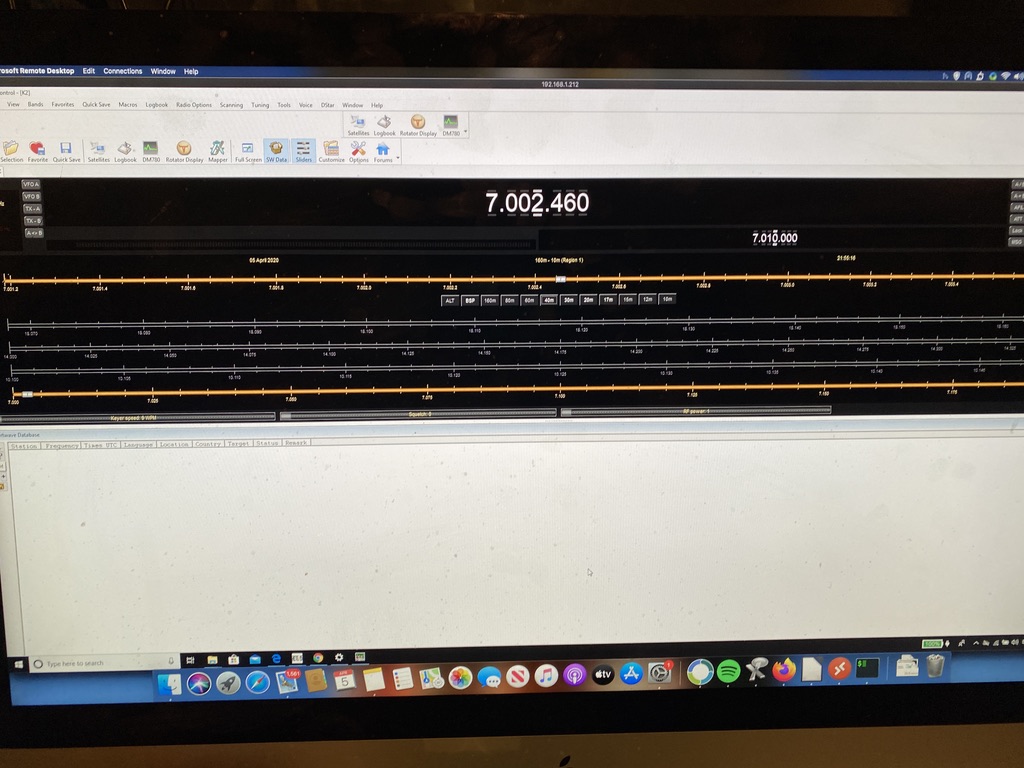

So the next step would be to test. For this i used the two main data modes I currently use, being FT8 and WSPR. I used WSJTX v2.1.2 and finding a ‘gap’ to press the ‘tune’ button. This would give me repeatable results. I am using the TS-690S internal SWR reading and a 2nd hand HF SWR Transceiver (YW-3) for the external readings.

| Band | SWR Transceiver | SWR Meter | Notes |

| 10 | 1.1 | 1.3 | |

| 12 | 2.2 | 80 | |

| 17 | 1.4 | 1.6 | |

| 20 | OFFSCALE | 2.5 | RX is very clear 5/9 |

| 40 | 2.2 | 1.1 | |

| 80 | 2.1 | 1 | |

| 160 | OFFSCALE | To be expected | |

| 30 | OFFSCALE | 80m wire ? | |

| 15 | 1.6 | 3 | Does the VV-3 work at this frequency ? |

| 12 | 2.1 | 3 |

| Band | SWR Transceiver | SWR Meter | Notes |

| 10 | 1 | 1.2 | 5 Watts is the min setting on the transmit |

| 12 | 2 | 2.5 | |

| 17 | 1.3 | 1.3 | |

| 20 | OFFSCALE | ||

| 40 | 2.9 | 1.1 | |

| 80 | 1.5 | 1.1 | |

| 160 | N/A | ||

| 30 | N/A | ||

| 15 | 1.4 | 1.5 | |

| 12 | 2 | 2.1 |

I am really impressed with the S.W.R. on all the bands, whilst 20M gave a high reading, i suspect that the curve on this band is quite specific. Reception is very strong, so the wire is doing its job in selecting the fequency nicely.

Whilst I wasnt expecting 160m and 30m to be available, for thorughness and future recording, added them (should of done 6m in hindsight). I was happy to see 15m and 12m resonating nicely with low S.W.Rs on of 1.6 and 2.1 respectively.

I will upload a gallery as there is so much evidiential data to show,so browse thru at your lesuire.