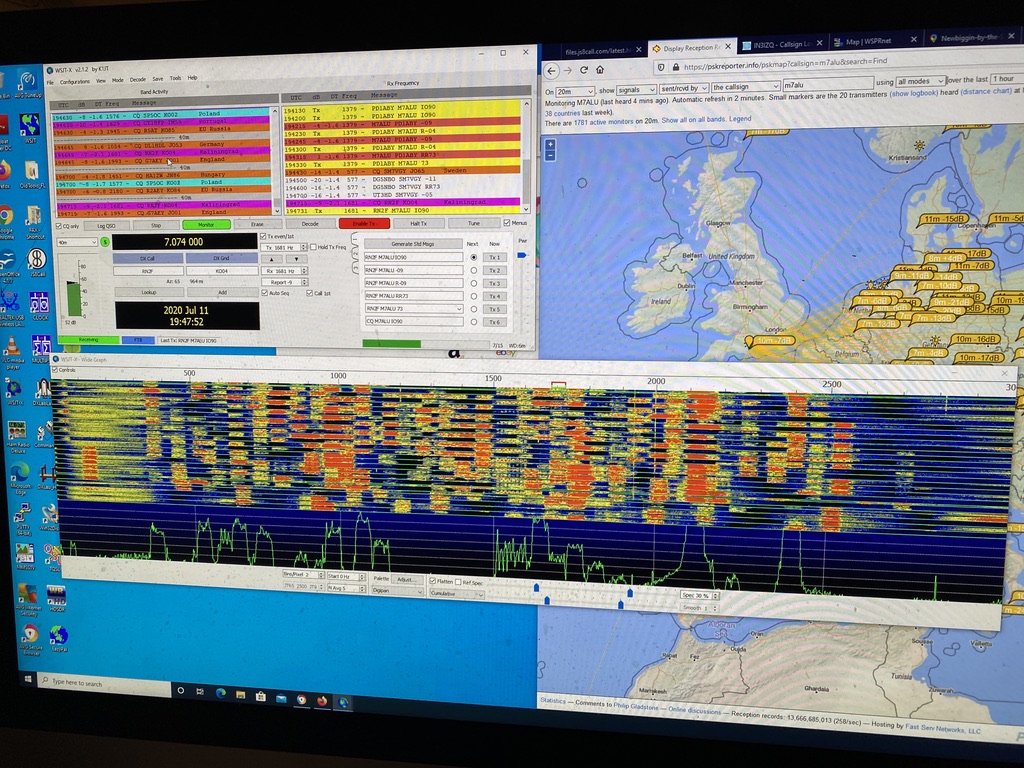

Its been a lovely warm weekend down in Dorset, and that seems to have affected the propagation. I had a great time on FT8 and JS8 Call, reaching amazing distances and really good signals being put out and received. I had many logged contacts and good signal reports.

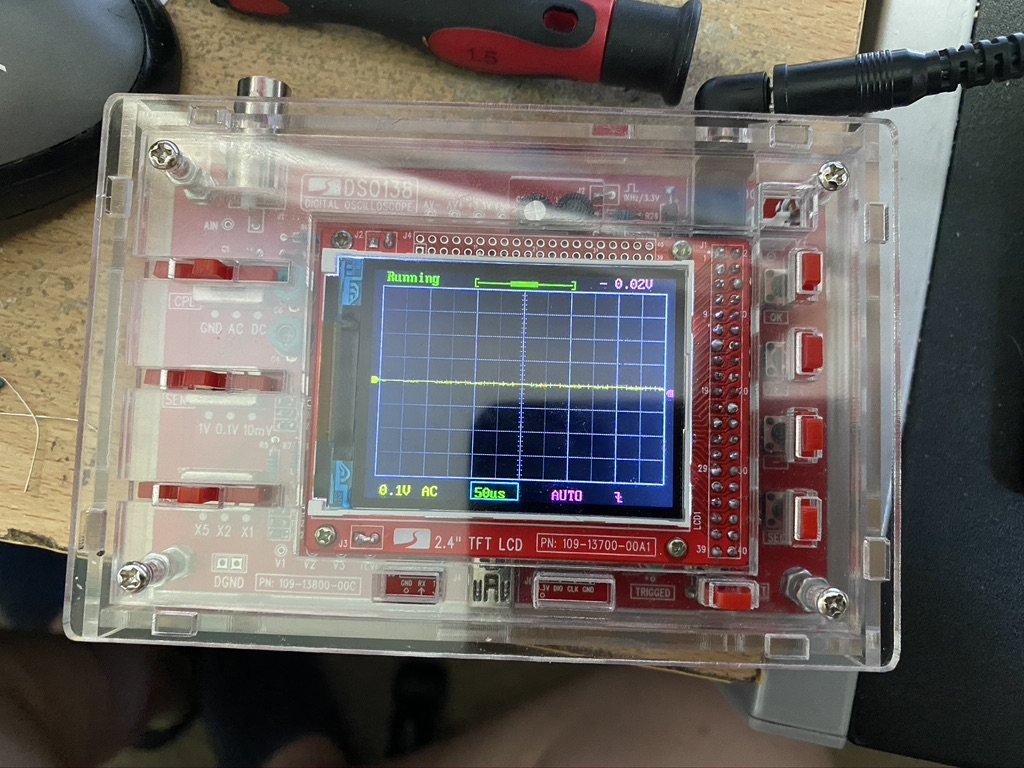

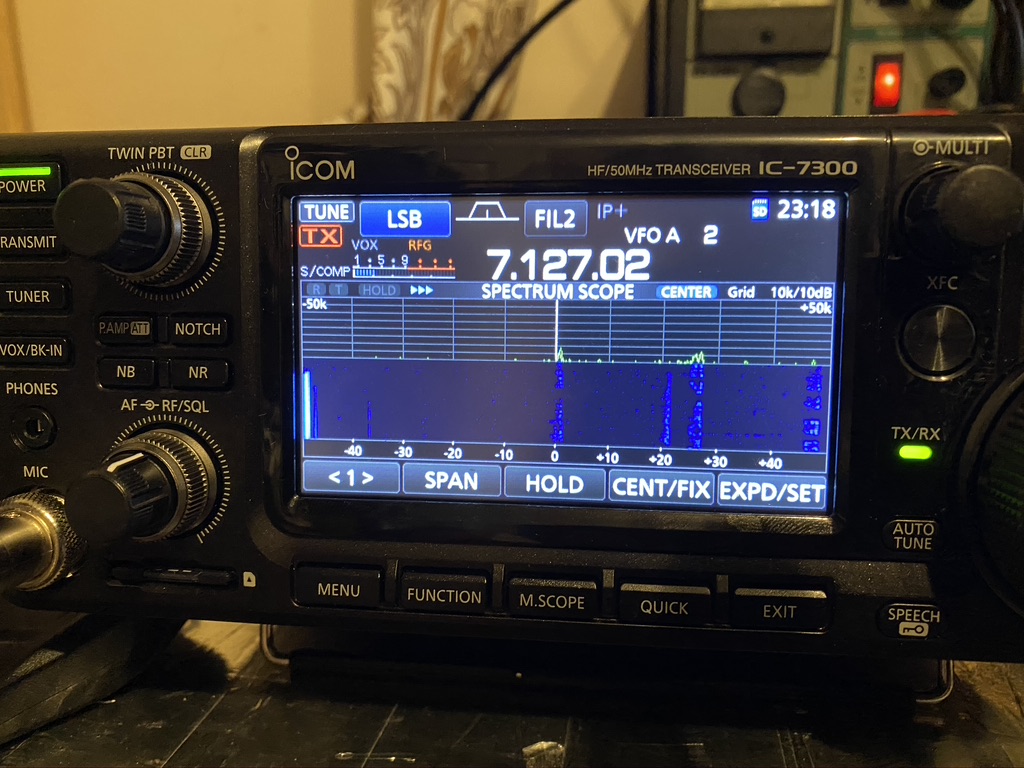

By the evening 40M got as busy as I have *ever* seen it, as shown in the picture above i switched about the bands and was making contacts on 15M as well, it was the best conditions I had seen so far !

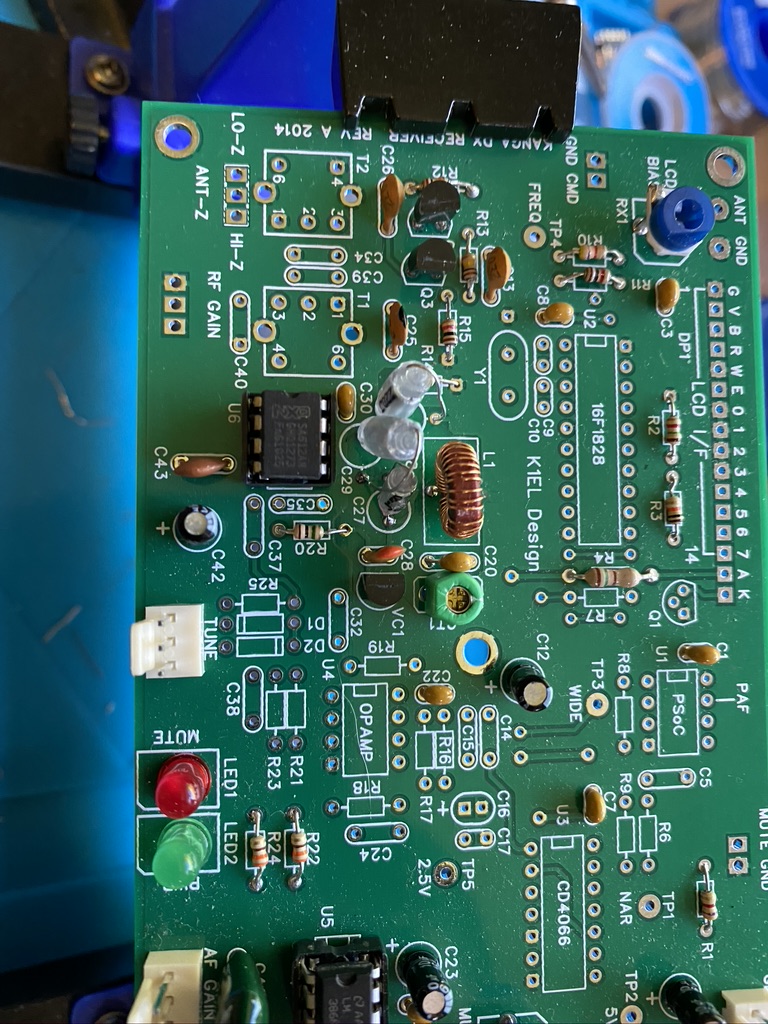

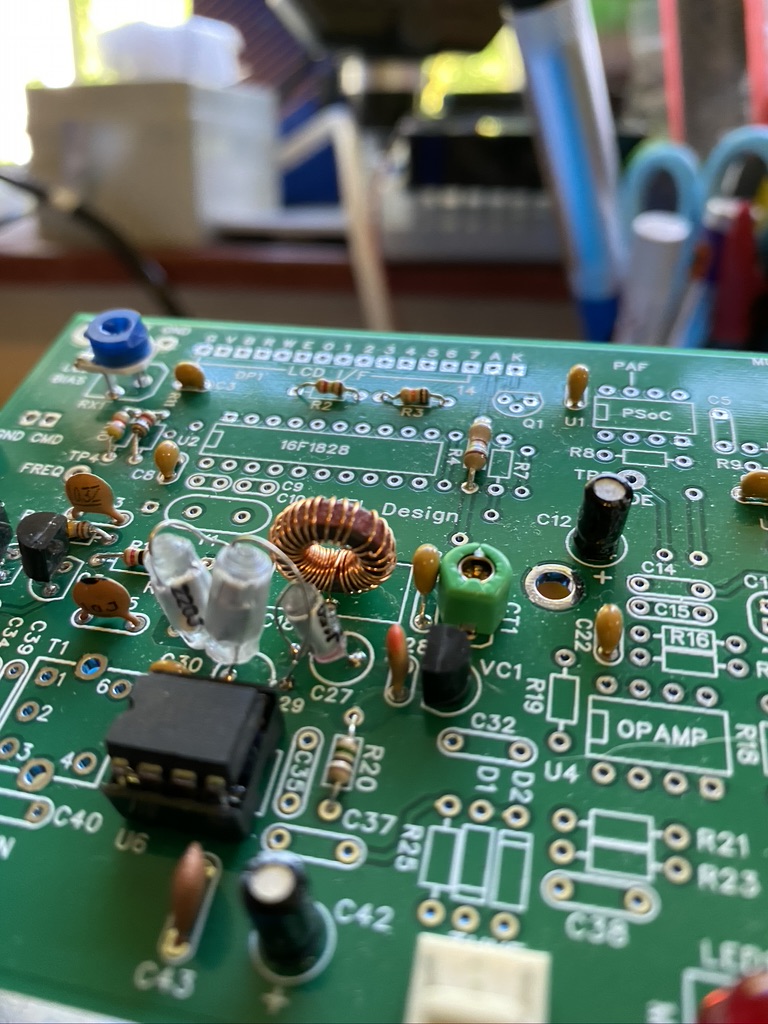

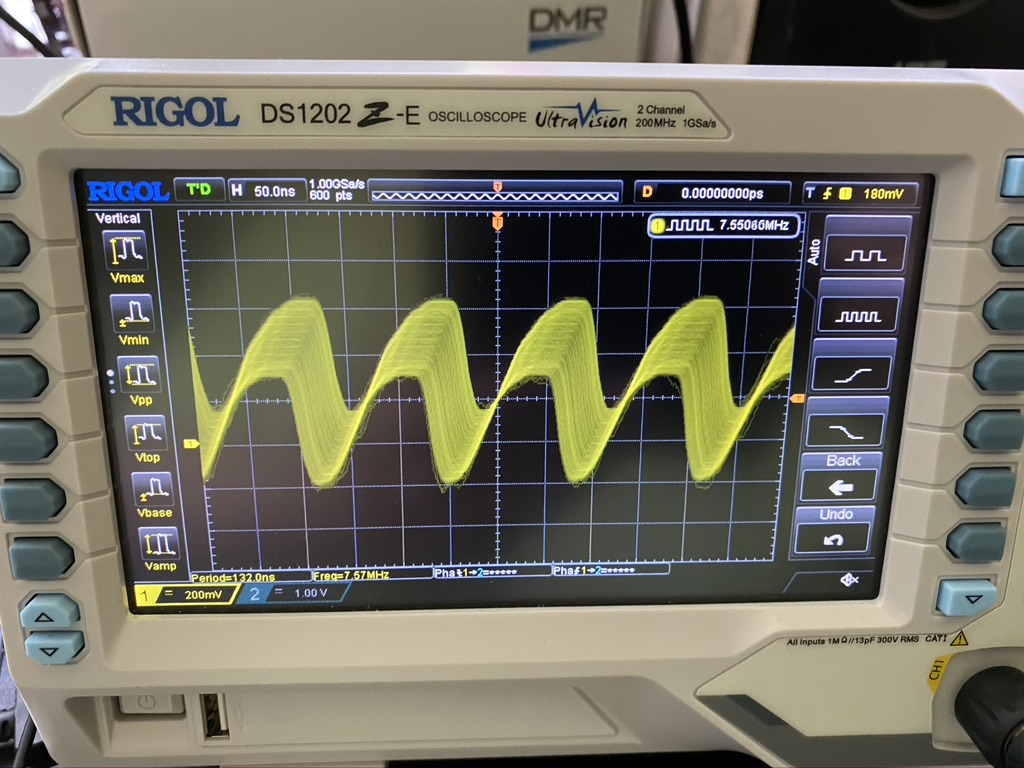

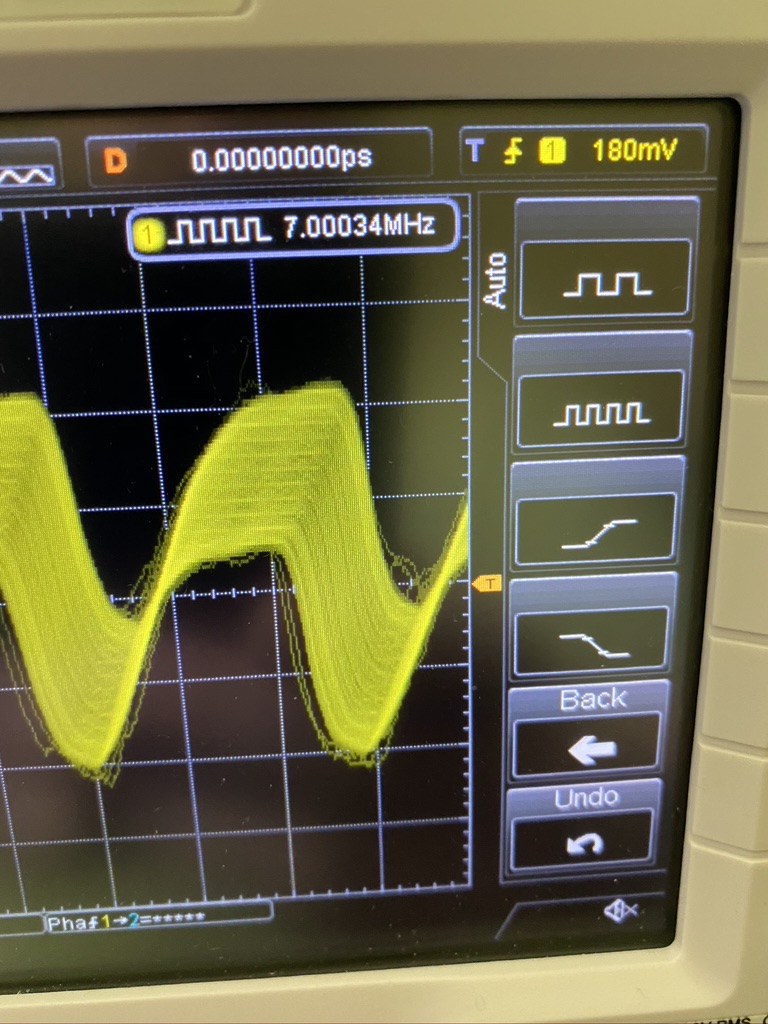

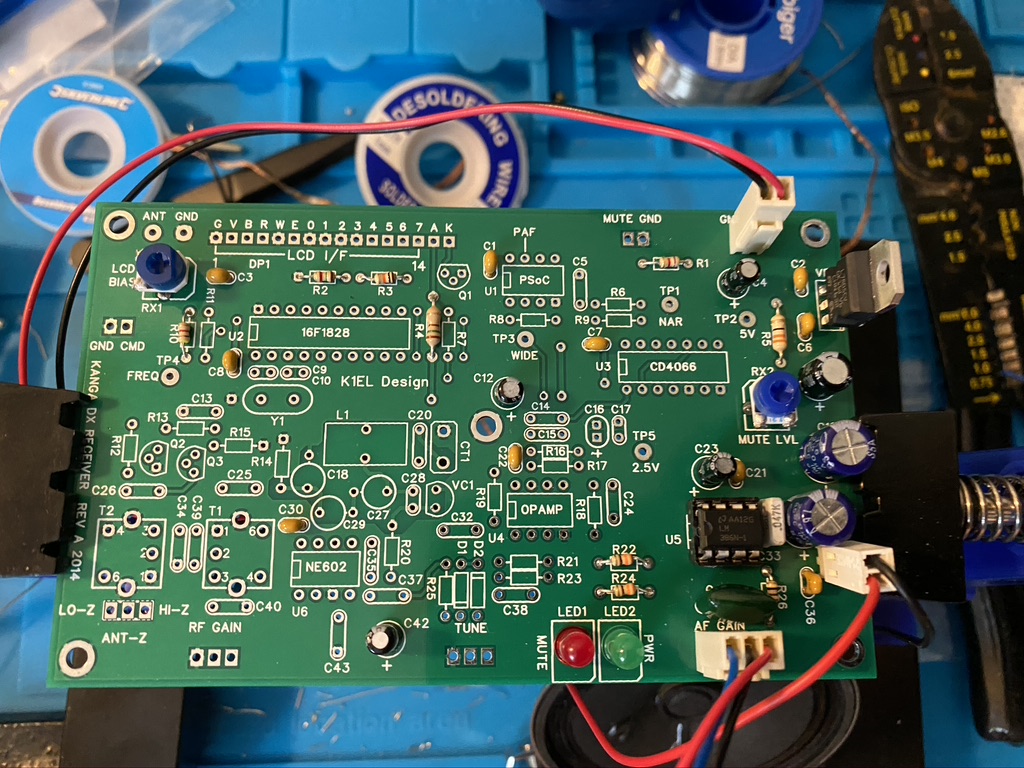

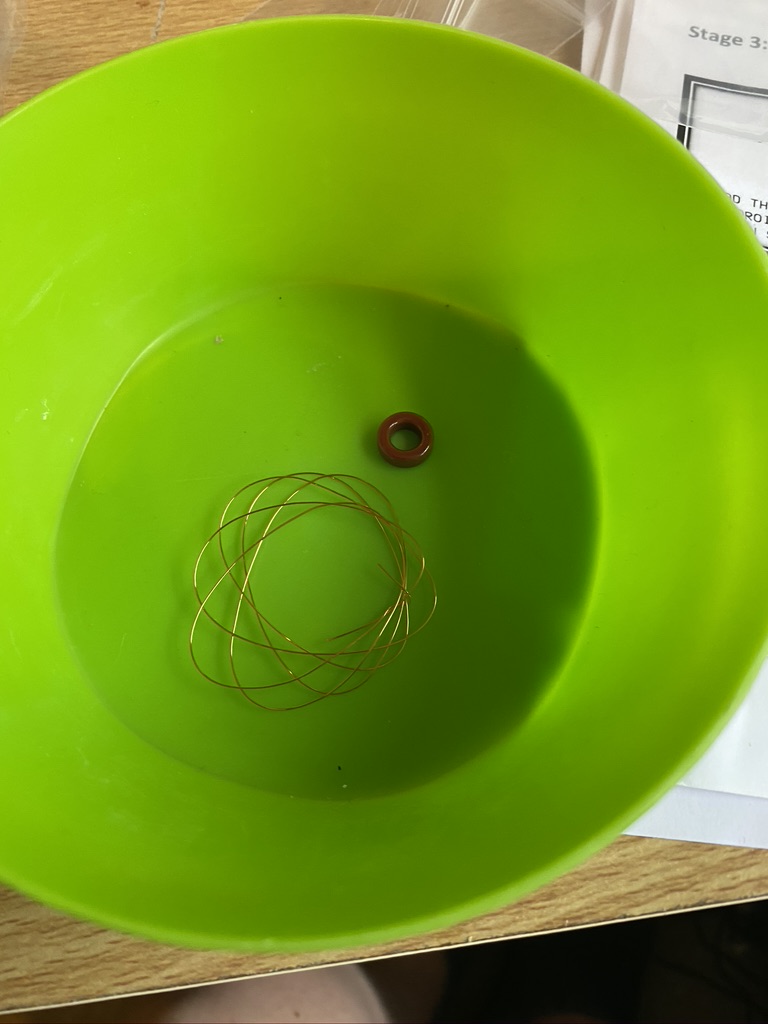

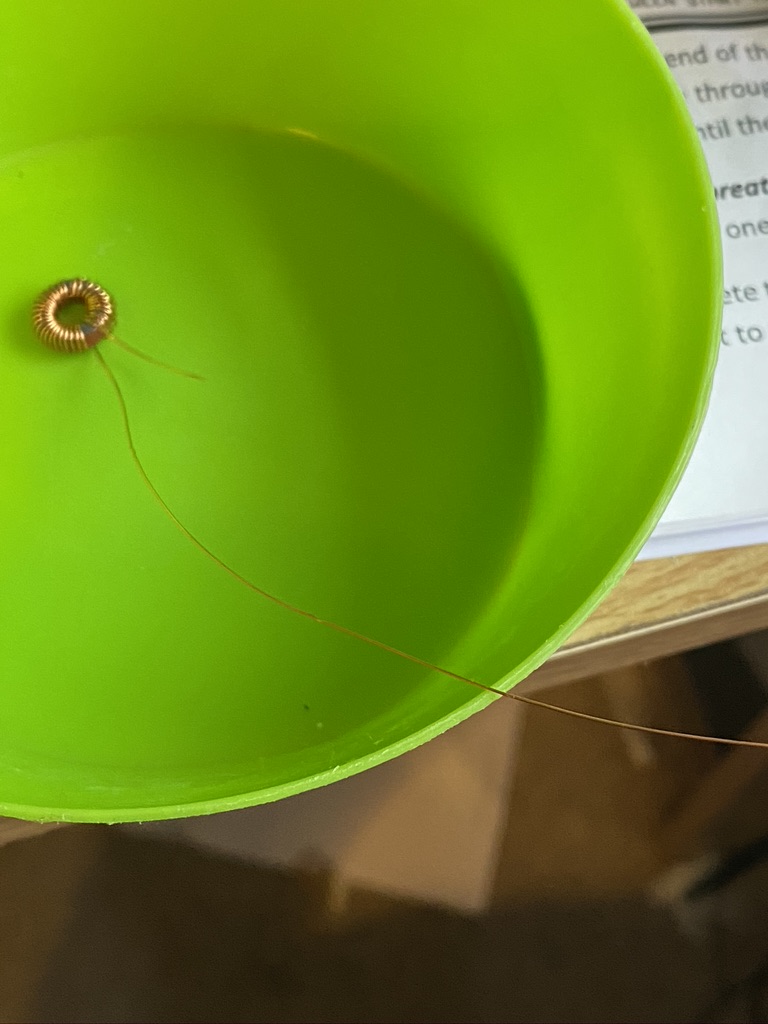

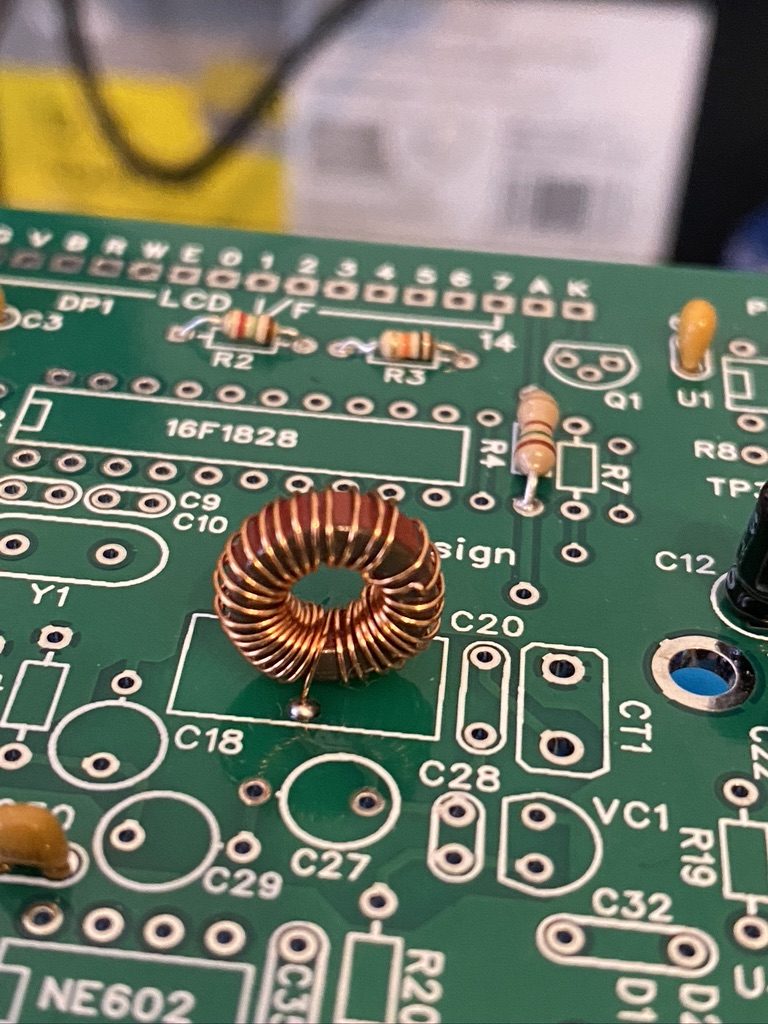

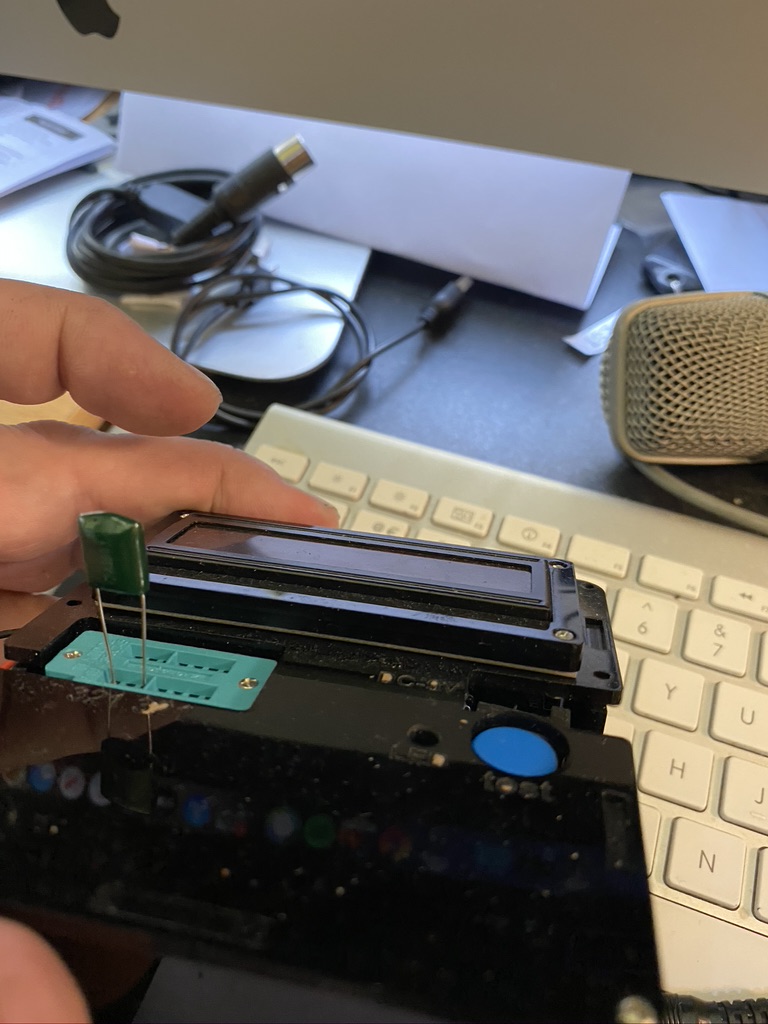

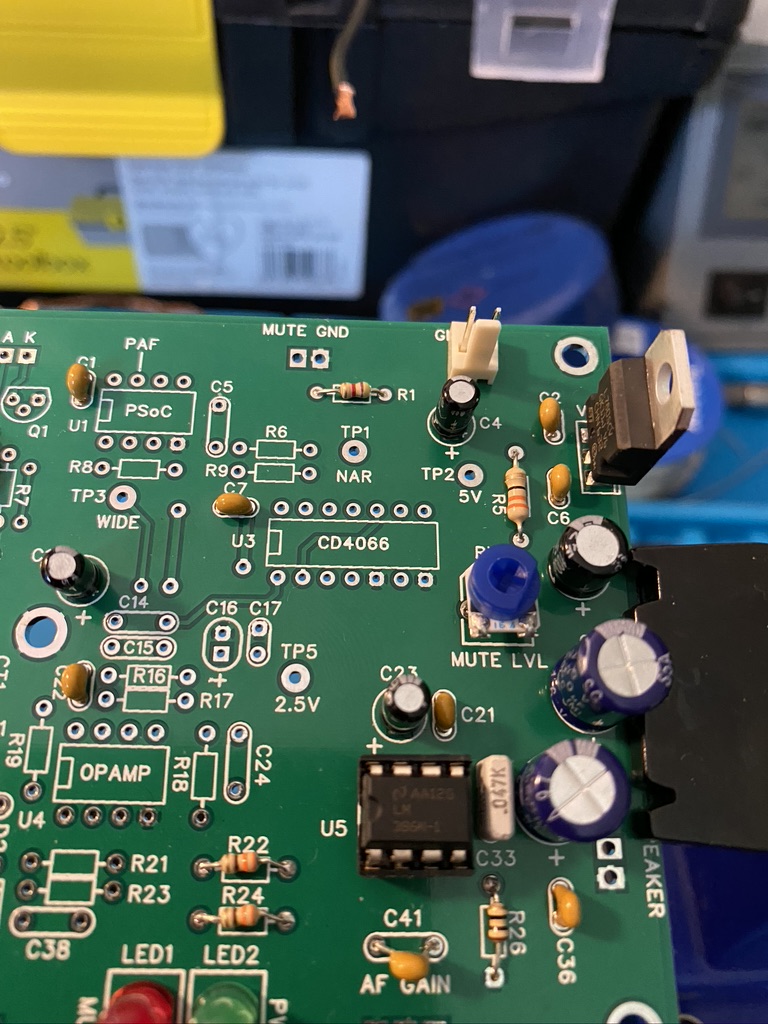

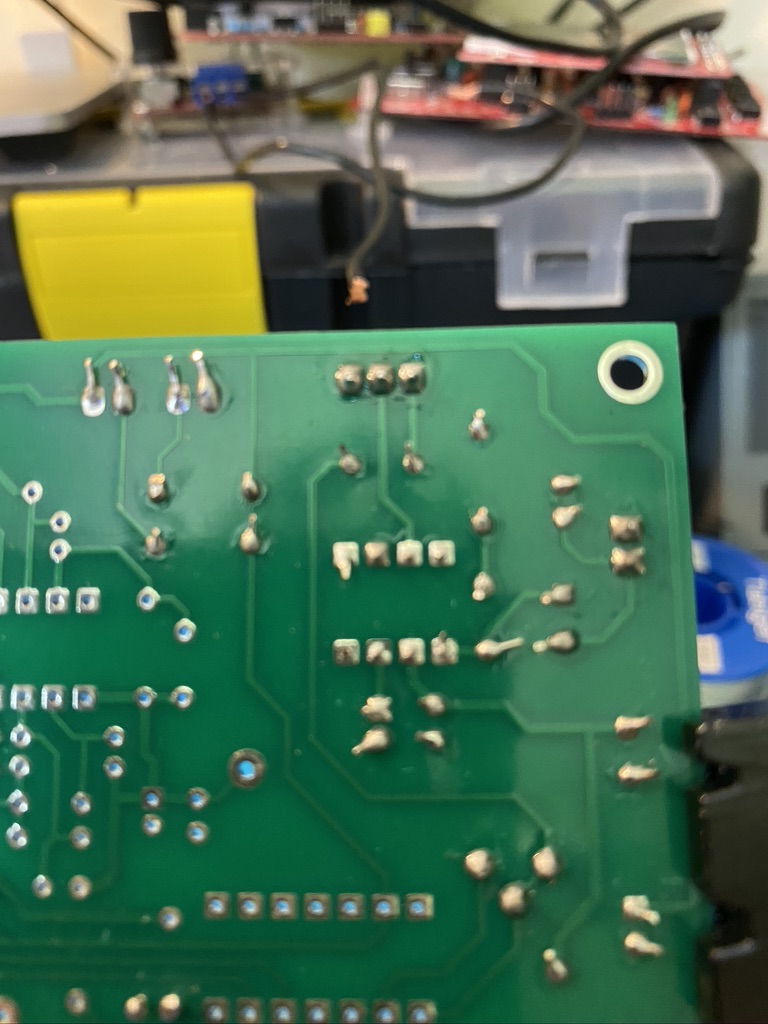

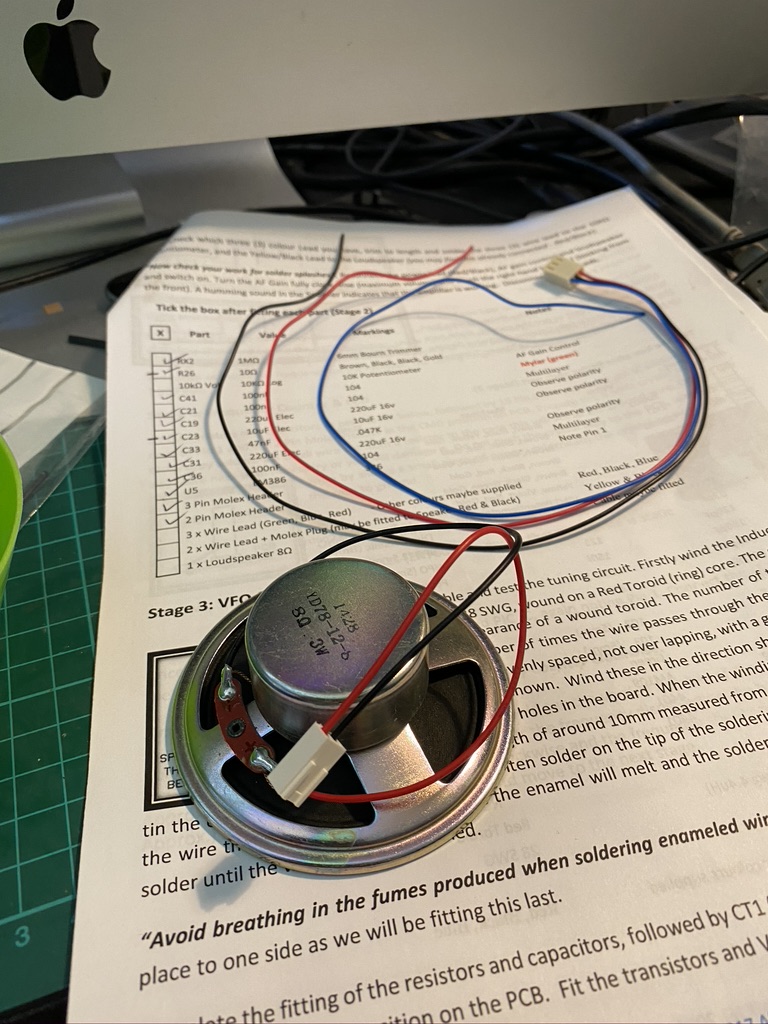

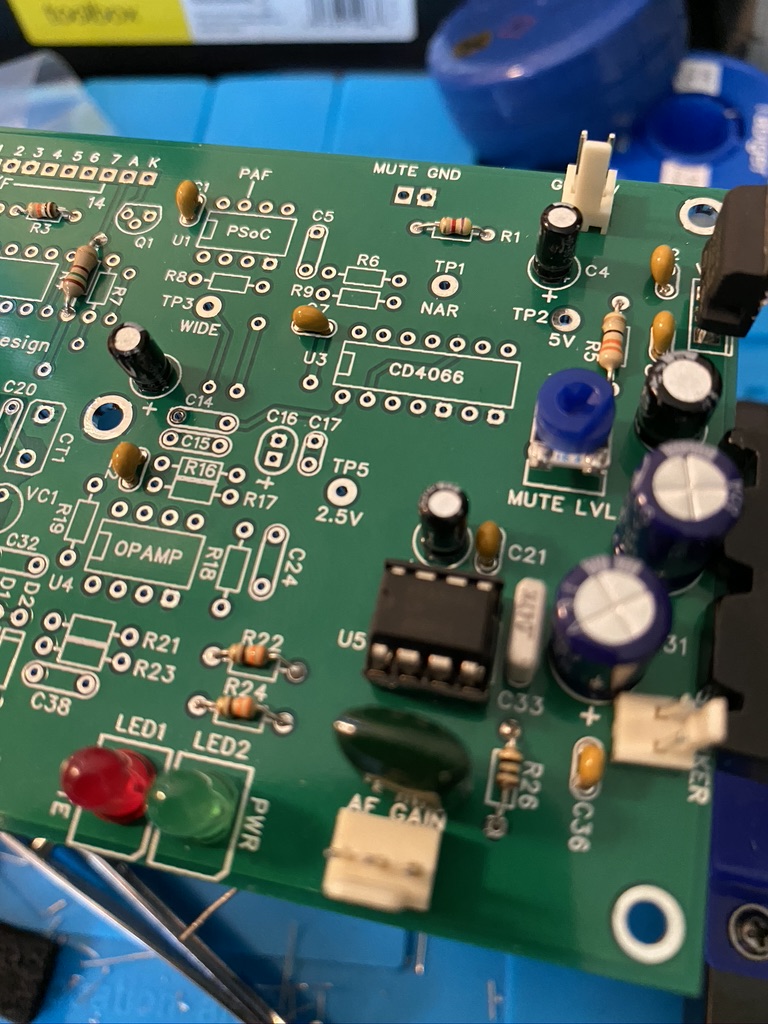

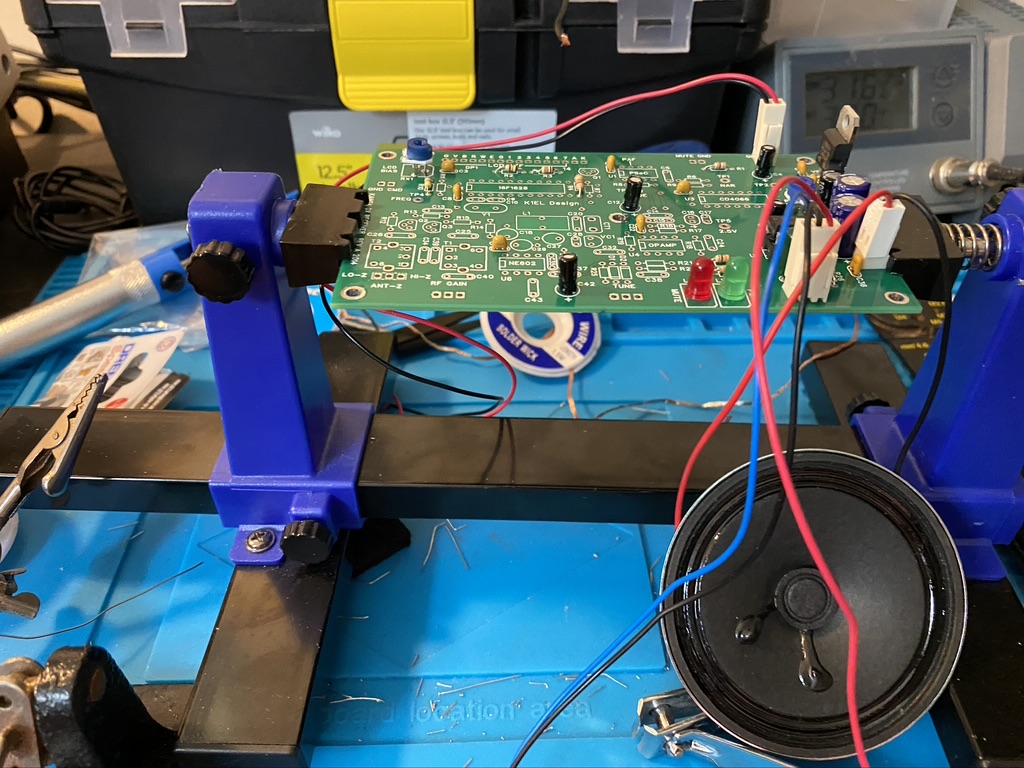

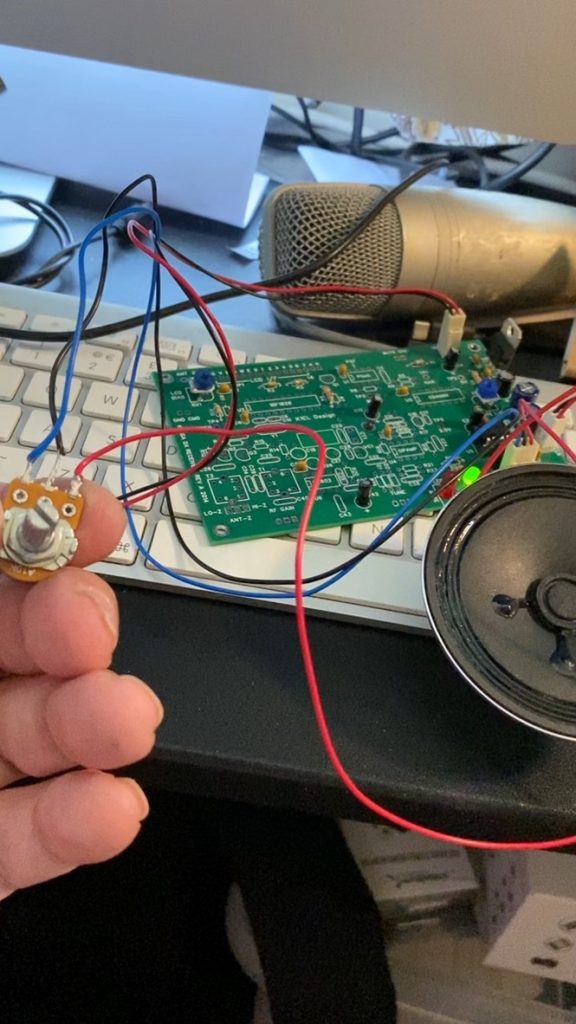

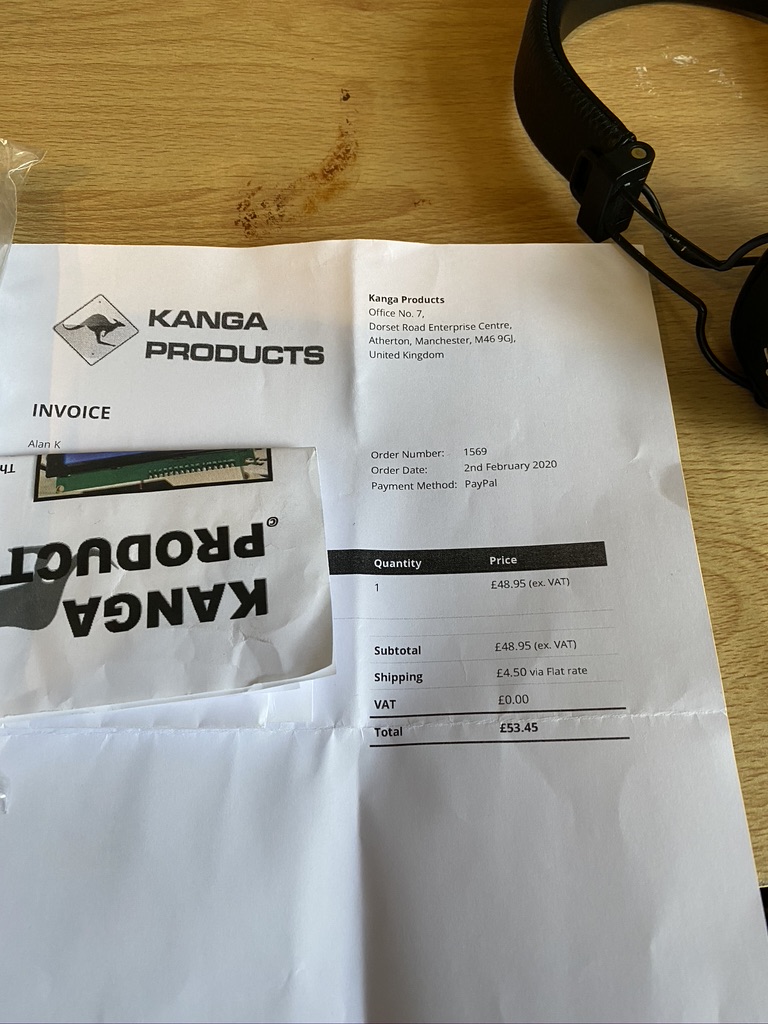

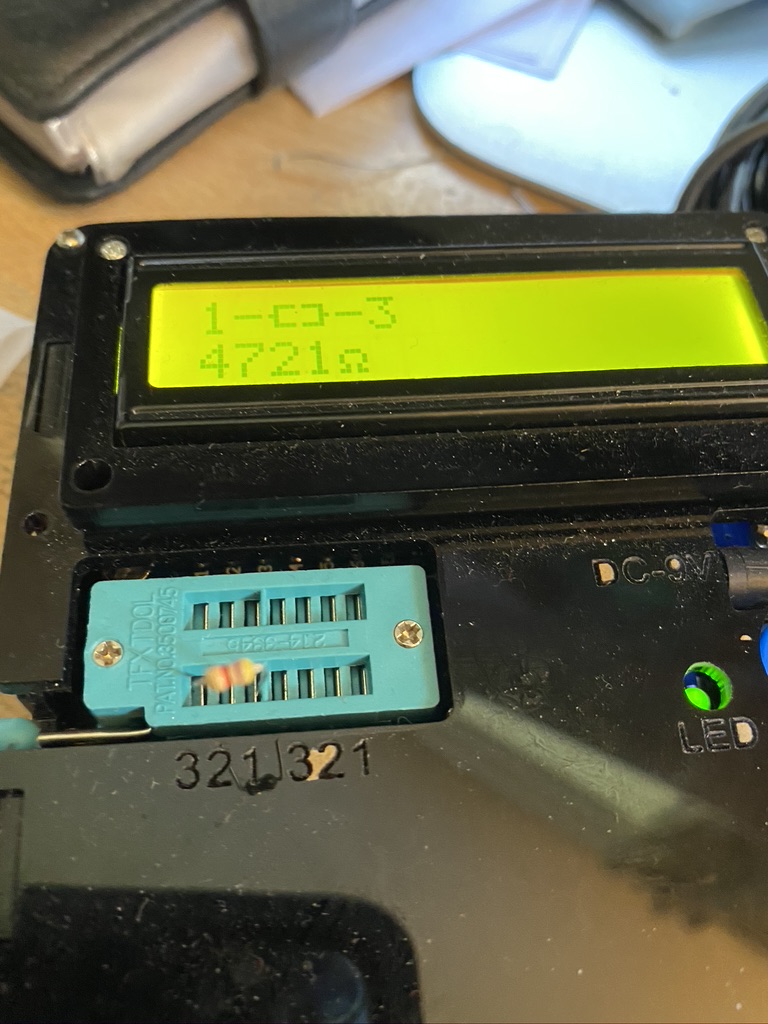

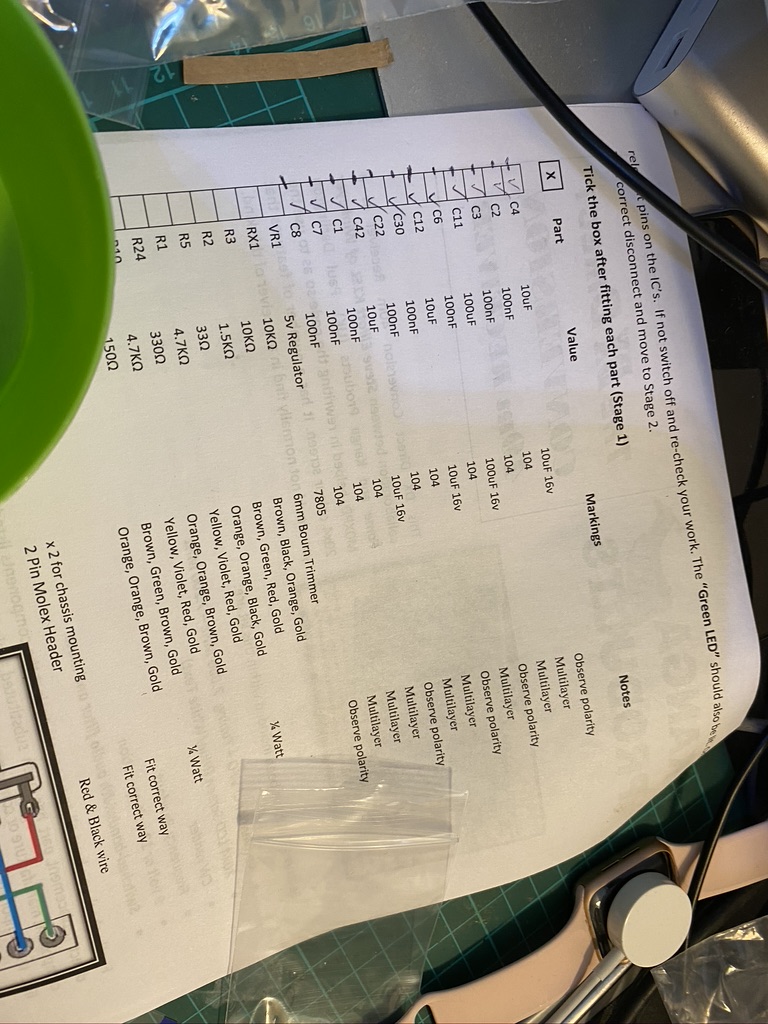

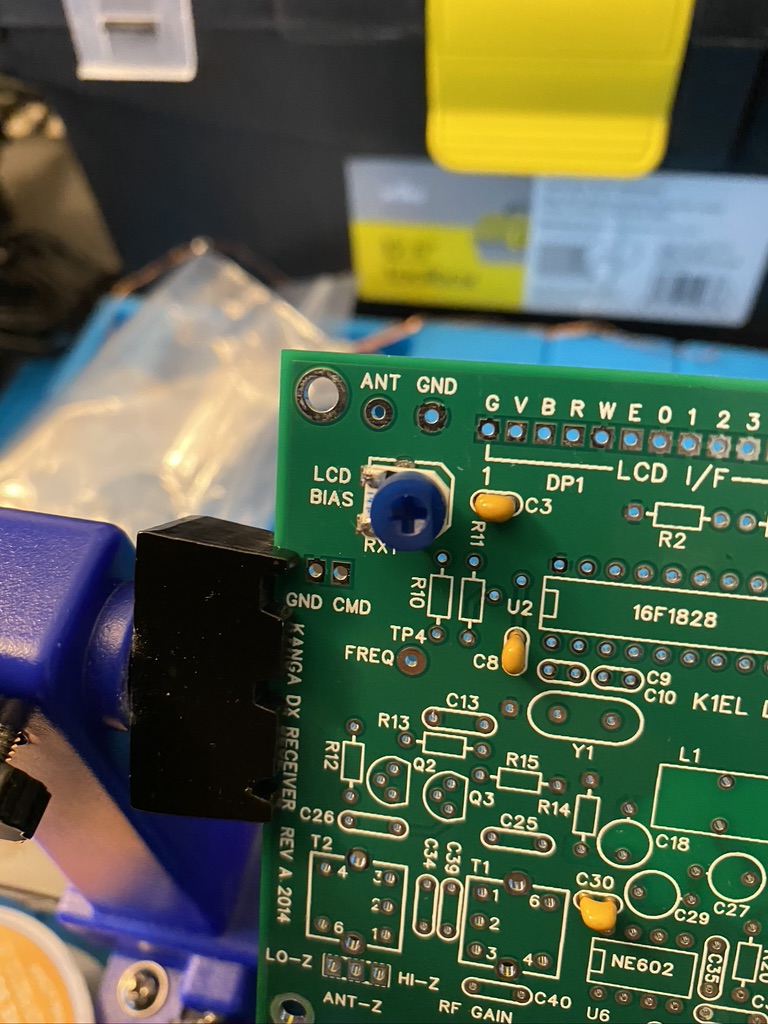

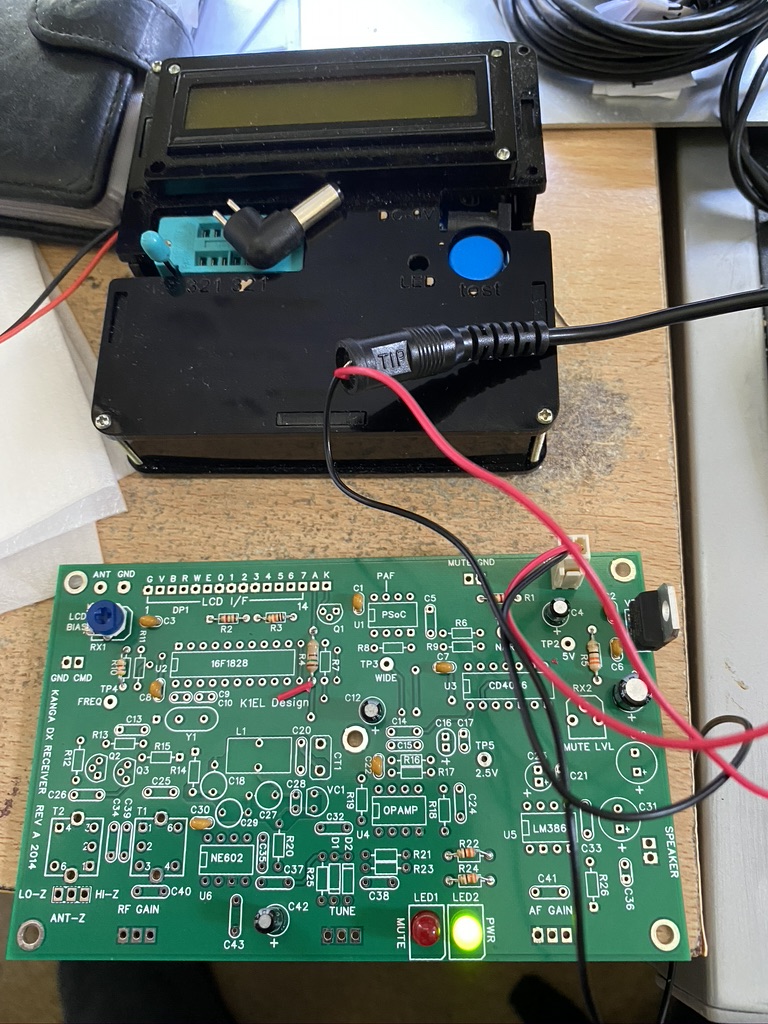

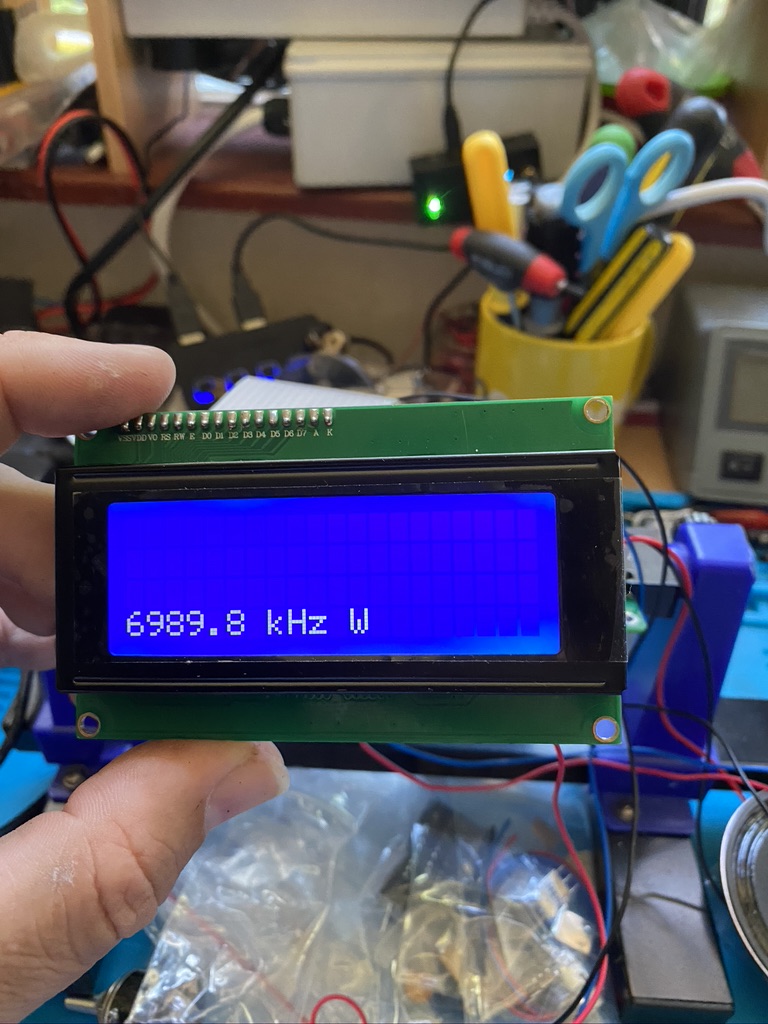

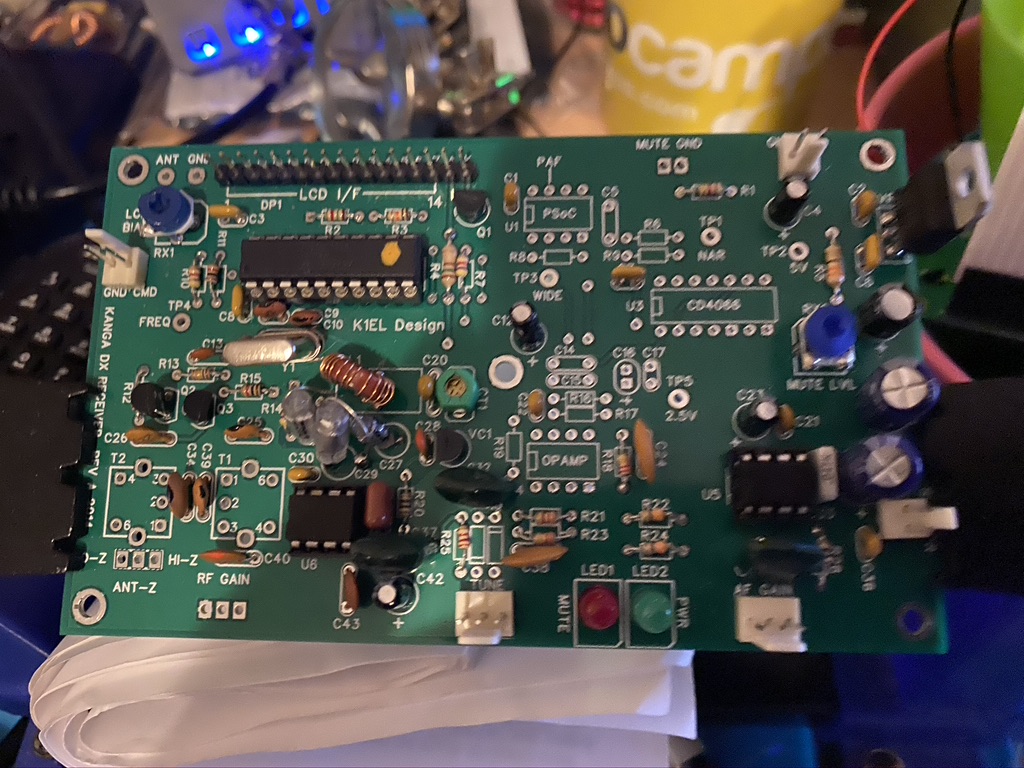

After a break of sometime, I have resumed work on my Kanga Kit – this fits in with the news I’m putting below, but I have a big thanks to John Clements who helped me fix a fault with the kit I was unable to locate. John found the issue (soldered pin-header together – hidden by the plastic) and returned the now working Kanga kit to me ! I have resumed work and am taking my time – I’ve completed more work on the resistors and capacitors on the Active BPF.

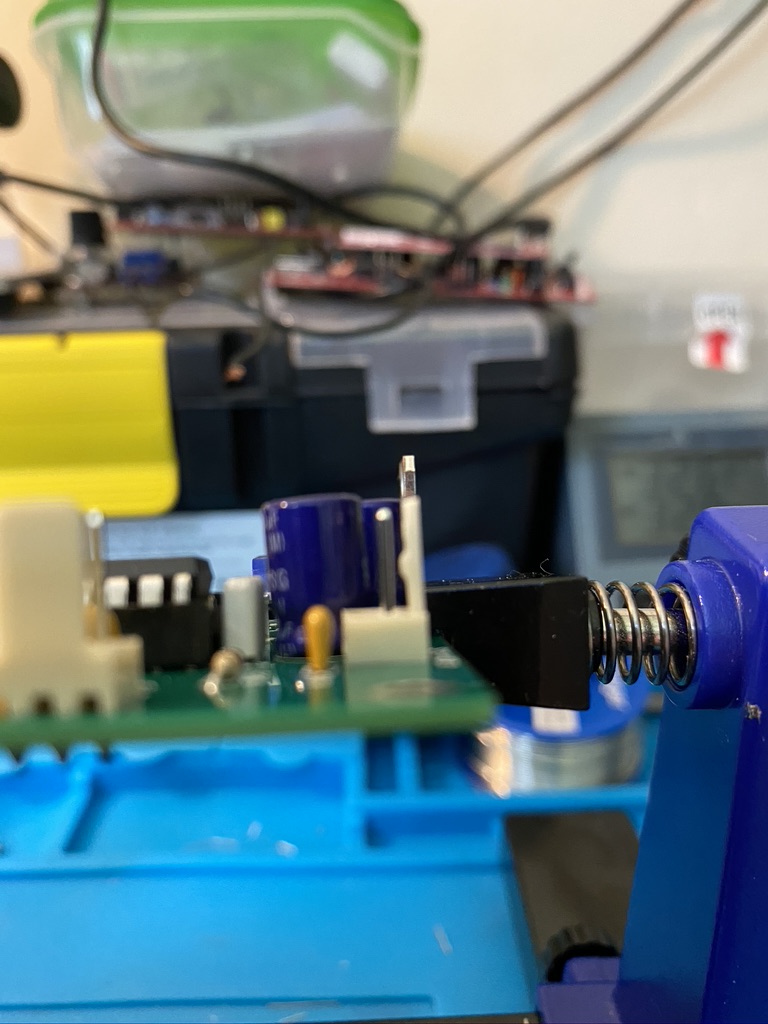

I’m taking my time, esp as the board is now quite ‘busy’ – the next step is to add diodes and IC’s. Its really close to completing the build, but taking my time to ensure no more mistakes !

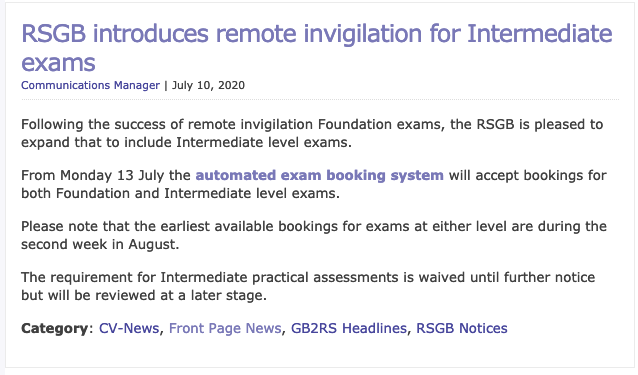

As shown in the picture above from the RSGB site Intermediate exams will be available from the 13th ! (in 8 minutes time as of writing) i’m very excited that i will be able to book my exam and get use more wattage but also gain more insight to a very interesting hobby as I continue my amateur radio development.

Whilst the practial assessment is waived currently, i will continue to build my Kanga Kit, so if the issue did come up of what Kit I did build, this is well recorded and documented.

To close the evening off I had a splendid evening enjoying the good propergation and just listening to the QSO’s on 40m. The ICOM’s filter and noise blanker are amazing, SSB has never sounded so good.

What i really like about the 7300 is the ability to visualize all or in very close range the frequency. I can easily find conversations happening and enjoy what is being talked about and the signal reports. Almost everyone i hear on 40m is using 100W but the distances are still several hundreds of miles – in particular hearing about life on Guernsey was very interesting – seems they are Covid free and back to some ‘normality’.

Well, heres waiting on being able to book my Intermediate Exam and enjoy more contacts around the world !

- UPDATE – Have booked Intermediate exam today (13 June) for in August for more time to do a structured revision plan and passing !

- Am still planning to finish my Kanga Kit ! making daily progress !

73 / Alan / M7ALU