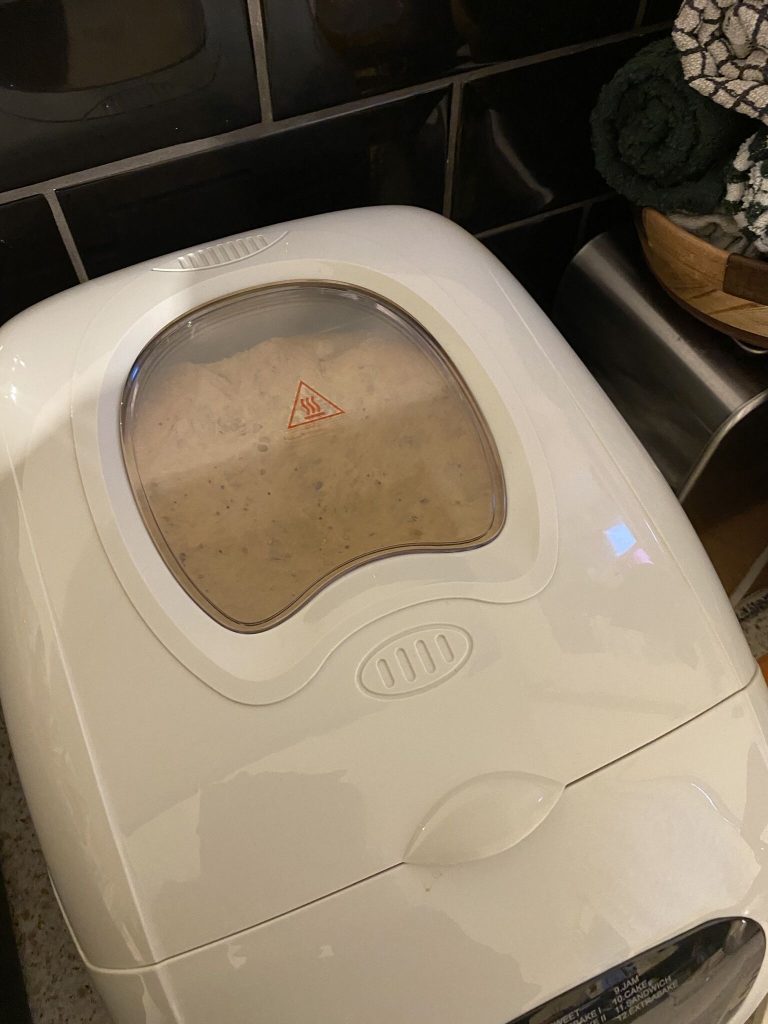

Another fine day of English weather, typical for the season herald the morning. Having been up early to start the bread-mix off, i set the alarm for day-break at 8AM. It was still quiet dark, but enough that i could wipe the mast down and look at the next set of tensioners for the 80m wire.

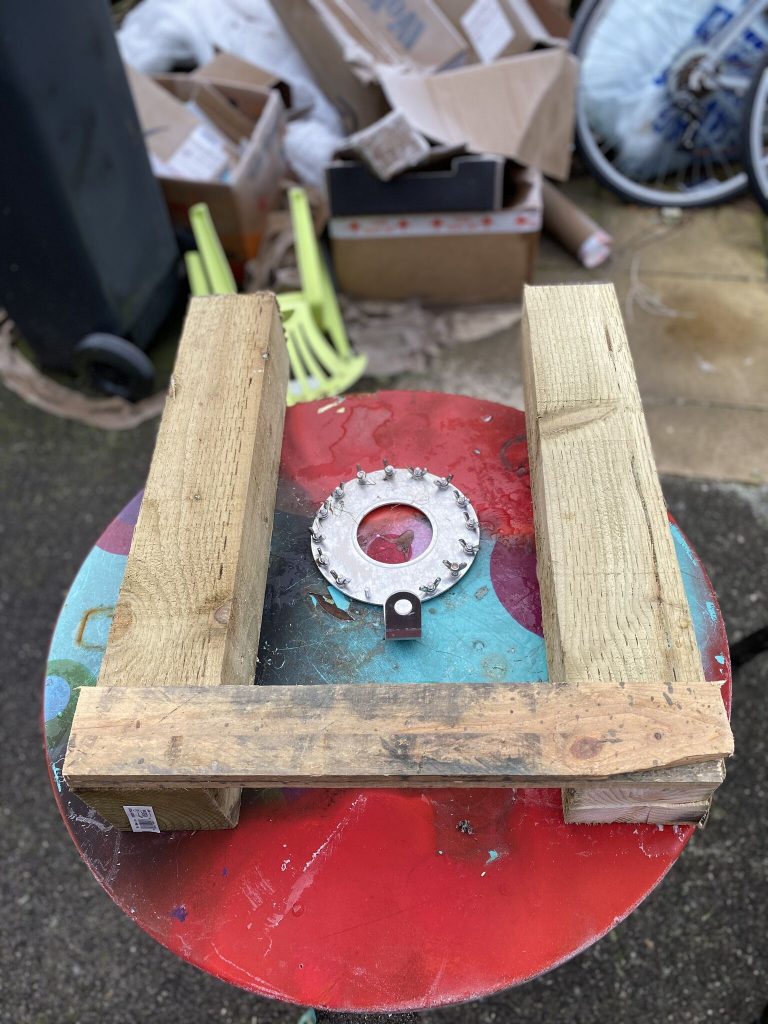

inspection of yesterday

whats left for today

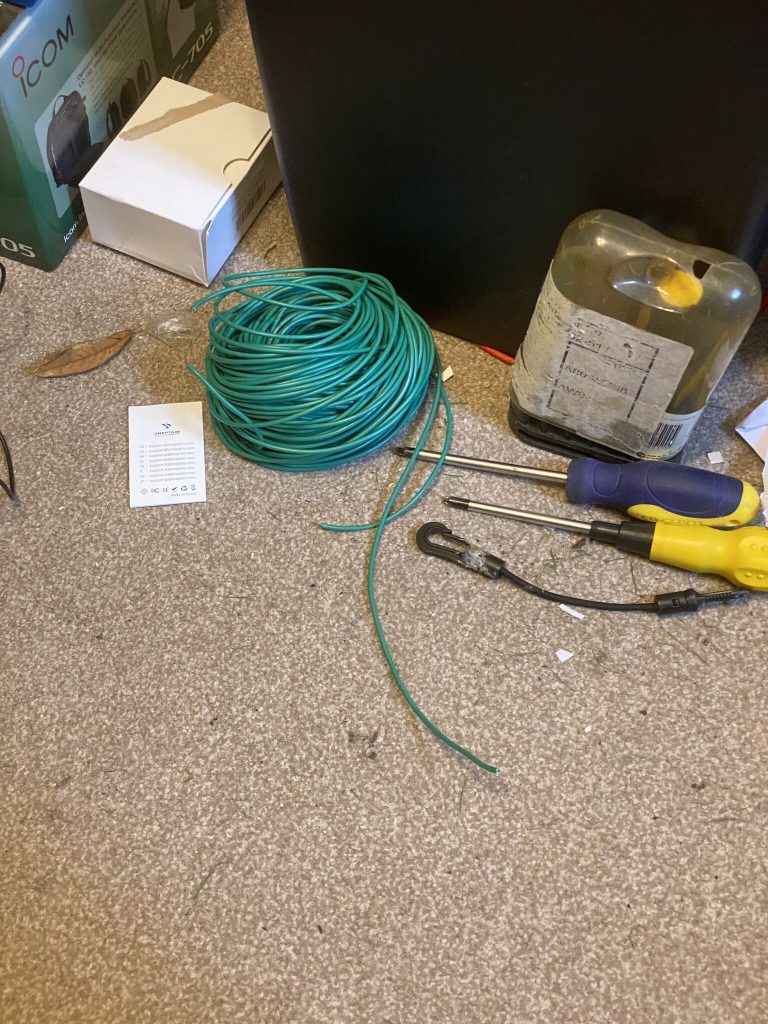

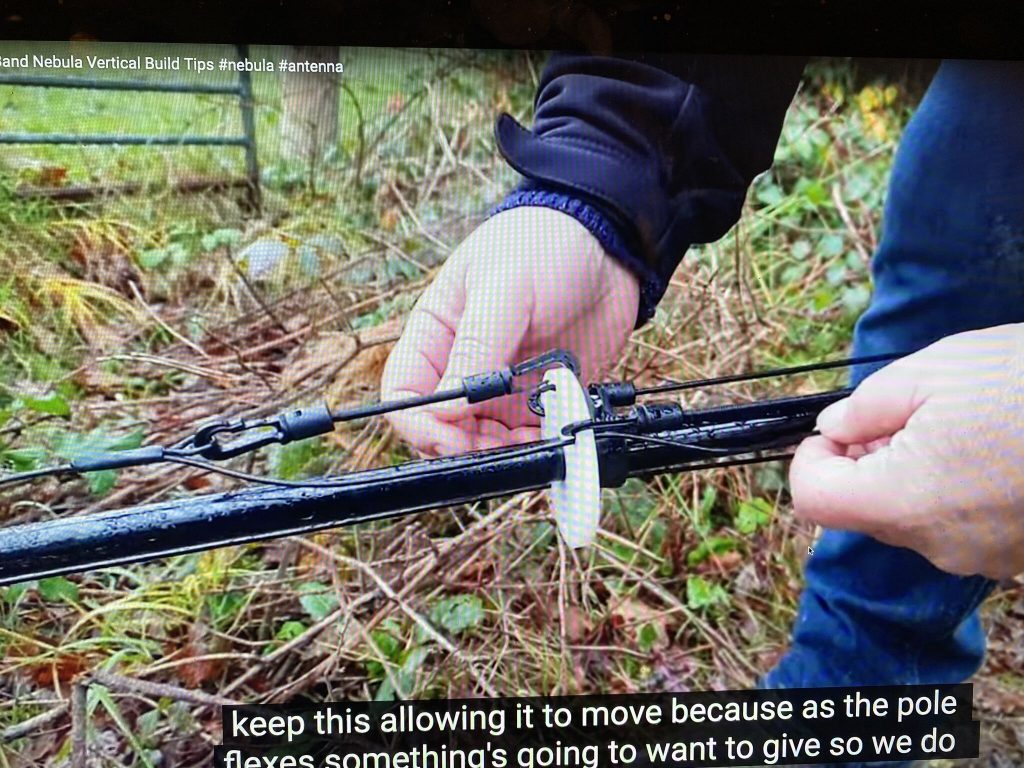

working out from vid

cant be that hard…

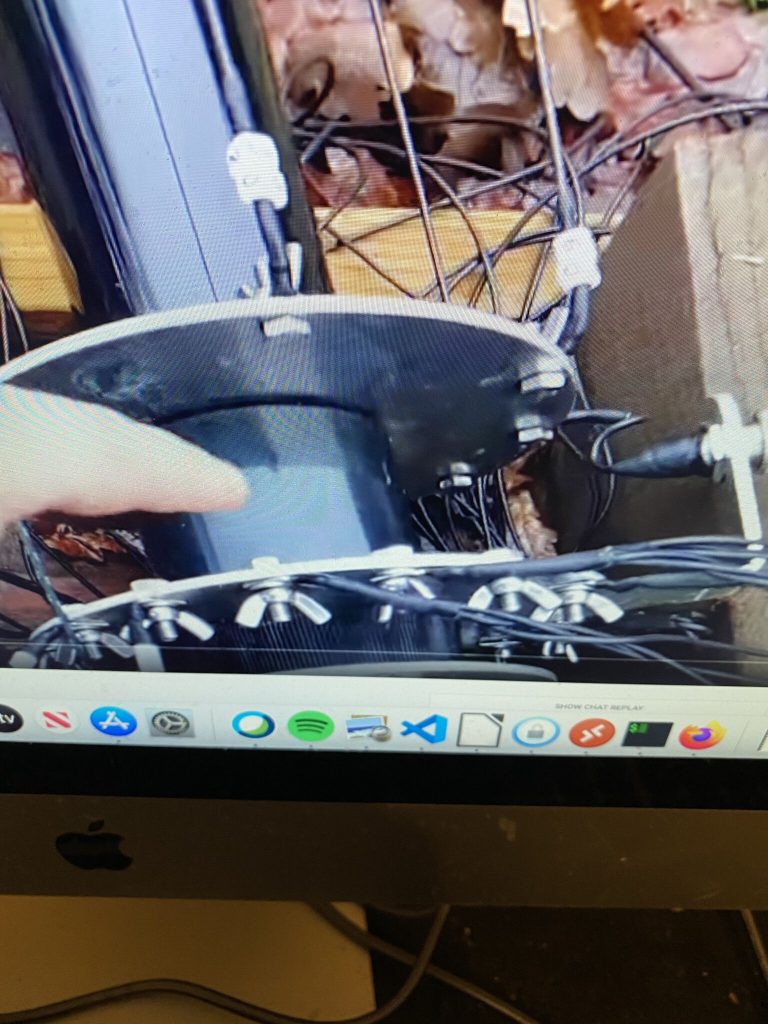

The initial tensioner at the 3rd spreader plate had held up over night, and was pretty good, having wiped the mast down to remove any moisture/rain i looked at the 4th and 5th plates for the next set of tensioning. I dont mind saying that i found it more wordy than how-to, so i watch Calum’s video again on how he done it and tried to remember how to do it out in the garden !

bread, almost done

ding

a bit more of tension

all the way up and down

flat-top bread

I managed to get the intial tension into the 4th spreader, and by now the aroma of bread was fillng the house. I took the bread out onto a rack to fim up and then tided up ready for a day of work – cant complain for 50 minutes of time – i like making small, steady progress.

pandas breakfast

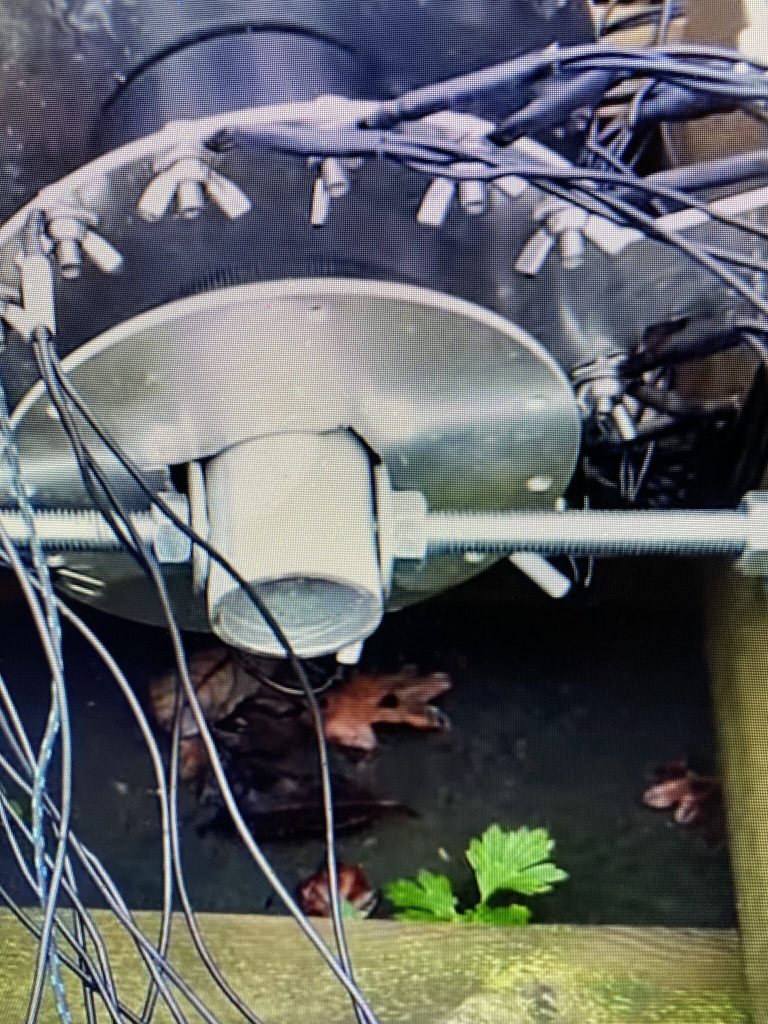

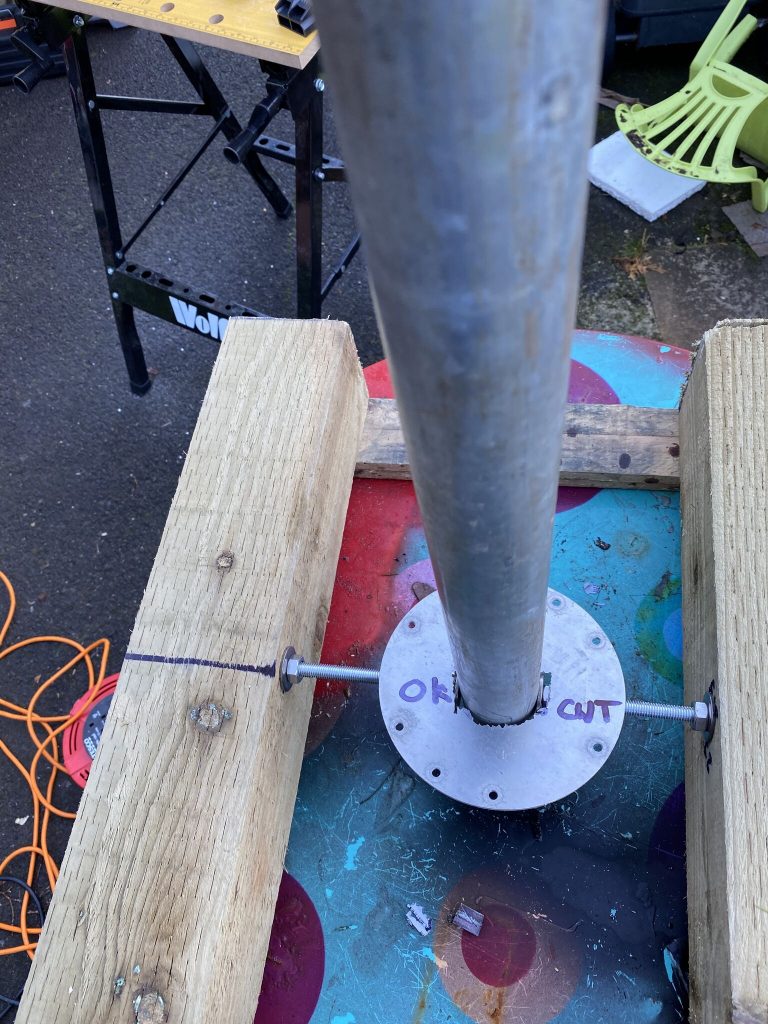

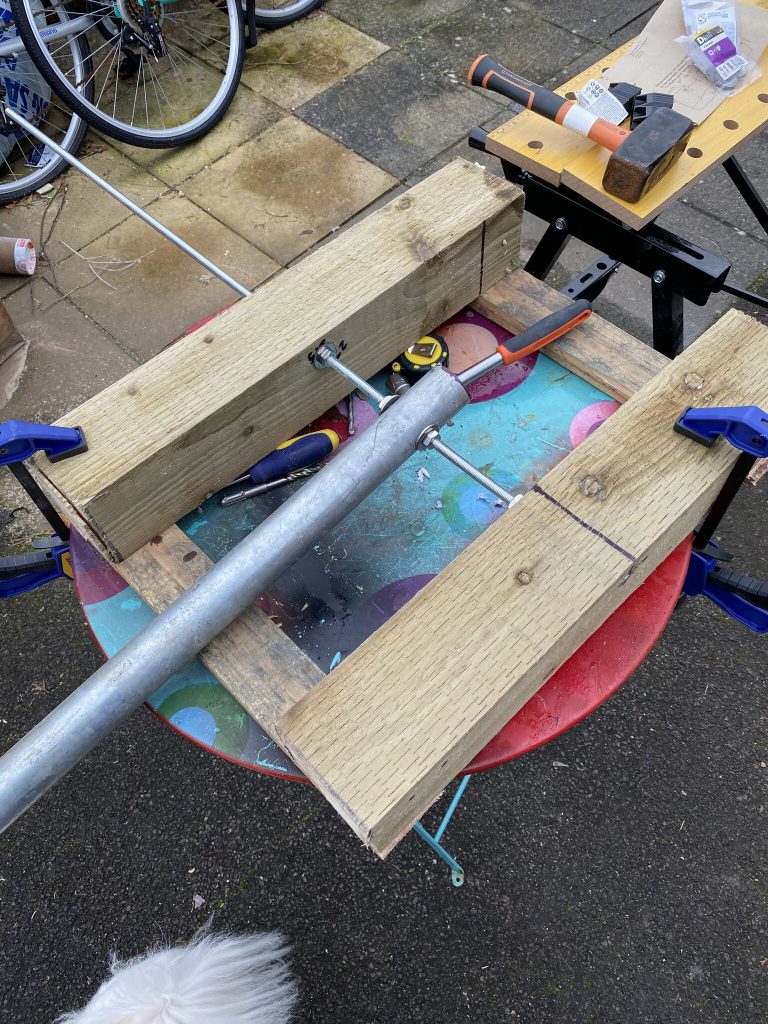

tube-fixture

tensioning

By now panda (aka Monica) had woken up for her breakfast, we both really enjoy havign fresh home made bread with no salt or sugar in it, it tastes lovely and is safe for both of us. I popped out to look at what i could do during lunch, and put the pipe-tube tensioner on to give me an idea of how all the upper side tensioner should work.. but to be honest i was still quite confused of how to get some decent tension.

hmm

tension…

at the top

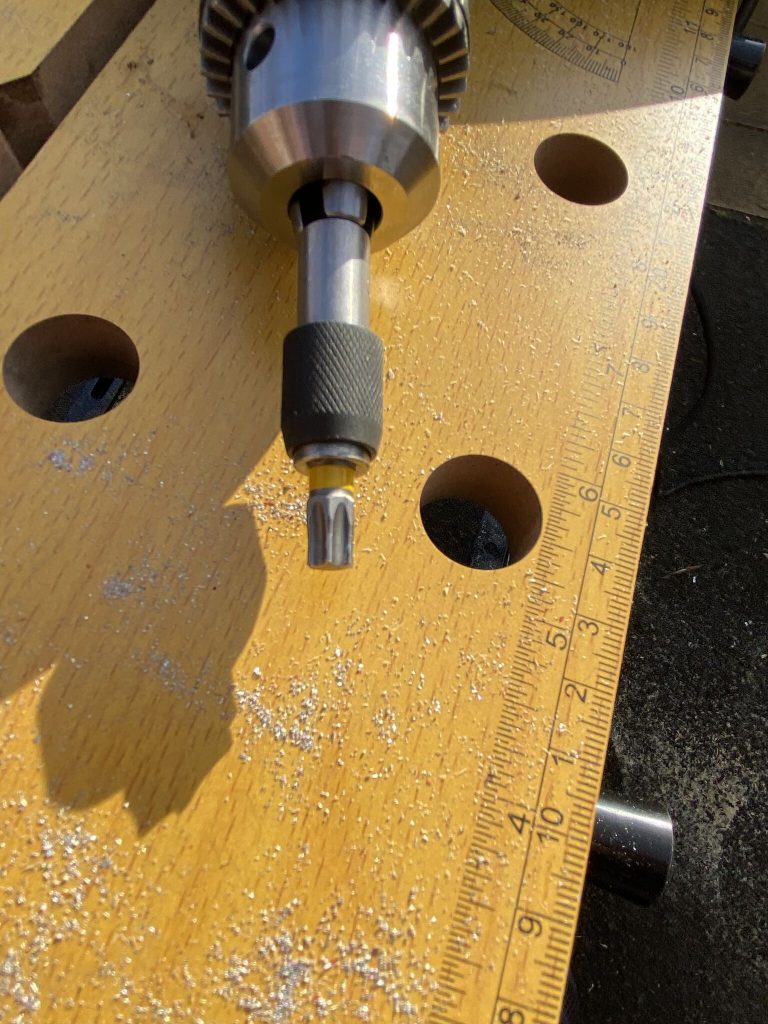

I spent my lunch break putting in the tensioners for the 4th and 5th plates. I don’t mind saying i found this quite stressful as I really wasn’t happy with the tension I had compared to what Callum had in his video.

By now i was honestly a bit miffed by it all and was eager to get back in with my day-job. I felt i had made some progress, but I wasnt very happy with the tension of the wire and also worried that the ‘doubling’ for the loops will create a linear load that will off-set the S.W.R. readings.

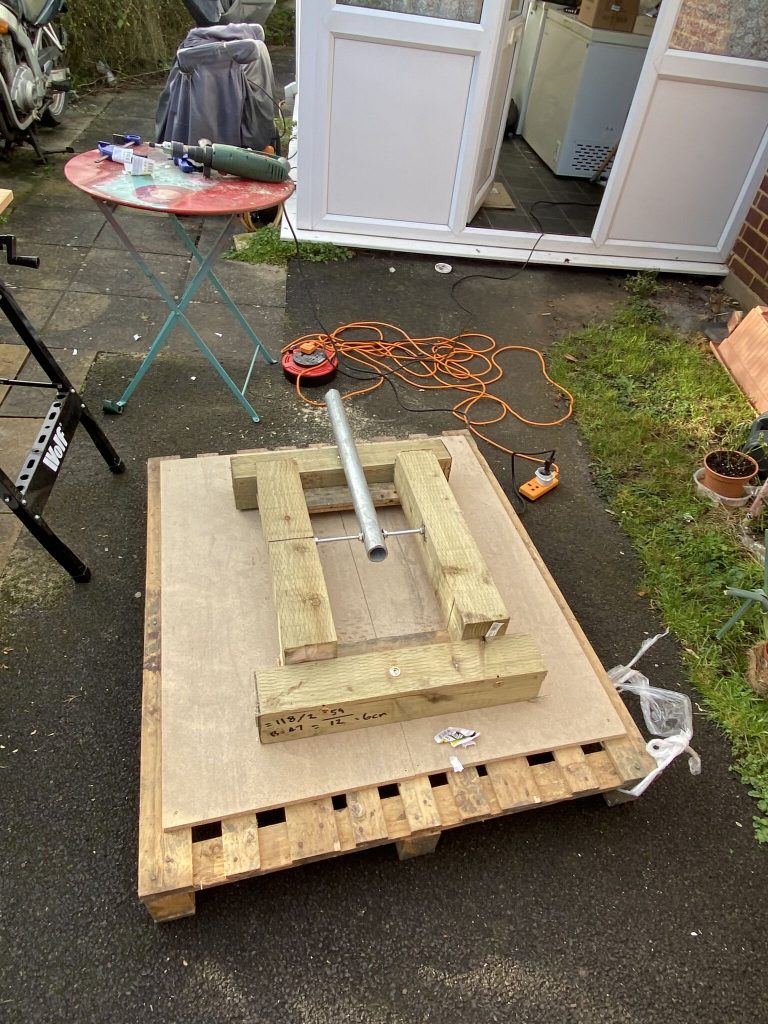

I came in, a little frustrated, but still glad i had made some progress midweek. The weather tomorrow looks quite abysmal with warnings for rain and wind where the next thing i have to do is to vertically erect the mast and guy it, before adding all the radials.

I will see how things are tomorrow morning, the worst thing would be to catch a cold/cough in the current climate and I’m not adverse to finding other ways to progress. The forecast for the weekend looks promising, but if anything this has been a ‘standard’ documented build so far, what comes next is the hard part, with all the unknowns of wire-lengths, loops and metal guy wires that could effect how the antenna performs..

Until next time, stay safe & 73

Alan / 2E0FWE